GRADED SEALS

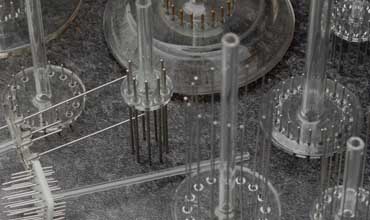

MOORES GLASSWORKS ARE A WORLD LEADER IN THE MANUFACTURING OF GRADED SEALS

With forty years experience in the industry, Moores Glassworks know the most reliable methods of creating glass-to-glass seals. By using our unique tried and tested methods, we create a graded seal to join the glasses.

A graded seal is used when to materials have different coefficients of thermal expansion. In this case we use a series of intermediate sealing glasses between the two different glasses. The linear coefficient of expansion must be close to avoid these seals from cracking.

Our experience in manufacturing graded seals ensures that our products will be durable and long lasting. We have been able to offer a wide range of products suited to applications in scientific, analytical and military industries.

A graded seal is used to overcome the difference in coefficients of thermal expansion. This is done by using a series of intermediate sealing glasses between the two different glasses on each end. The linear coefficient of expansion must be close to avoid these seals from cracking.

Other Glassware Products

TYPES OF GTMS PRODUCED

A matched seal GTMS is manufactured using a glass and a metal with a matched thermal expansion. This creates a tight vacuum bond between the two materials. In its molten state the glass is capable of wetting the kovar to form a hermetic bond. A matched seal gains its strength from a chemical bond between an oxide in the metal and the glass. At Moores Glassworks, we use this type of seal to ensure that your product will be safe and durable.

Through extensive research and experience Moore Glassworks have found that a matched seal will create a durable and hermetic bond.

A matched seal has many advantages, due to the matching coefficient of thermal expansion of the metal and the glass, the seal is impervious to gas and air. This makes it safe to use when feeding an electric conductor from one environment to another. As the metal and the glass have similar thermal expansion properties, the seal will expand and contract at the same rate when put under pressure. Moores Glassworks runs safety tests on each product before shipping to ensure that your GTMS is safe to use and fully functional.

With forty years experience in the industry, Moores Glassworks know the most reliable methods of creating glass-to-glass seals. By using our unique tried and tested methods, we create a graded seal to join the glasses. A graded seal is used when to materials have different coefficients of thermal expansion. In this case we use a series of intermediate sealing glasses between the two different glasses.

The linear coefficient of expansion must be close to avoid these seals from cracking. Our experience in manufacturing graded seals ensures that our products will be durable and long lasting. We have been able to offer a wide range of products suited to applications in scientific, analytical and military industries. A graded seal is used to overcome the difference in coefficients of thermal expansion. This is done by using a series of intermediate sealing glasses between the two different glasses on each end. The linear coefficient of expansion must be close to avoid these seals from cracking.

Using special and unique techniques, Moores Glassworks manufacture over four thousand various grades per month at our production facility in England. Our experience in providing graded seals has enabled us to offer a wide range of products suited to applications in scientific, analytical and military industries. Moores Glass can rely on their highly skilled team of glassblowers as well as state of the art tools and machinery.

Pyrex to Kovar is the most popular choice for a GTMS; this is due to the metal having a thermal expansion rate close to that of glass. This choice of material guarantees that the bond will be hermetic as the metal and glass will expand at the same rate as each other. Kovar is the perfect choice for a matched seal as it can withstand temperatures of up to 425C. The process of creating a GTMS using Kovar metal has been tried and tested by Moores for over forty years. A strong bond between Kovar and glass is indicated by a greyish blue colour to the seal. If the seal looks metallic, the bond is weak and the GTMS should not be used.

We are industry experts in both old and innovative manufacturing techniques, which is why we can guarantee you a safe seal. To ensure product safety, we regularly operate a random safety test in our factories.

Glass to metal seals are used in a number of different situations. As they are impervious to the elements, they are often used by military forces to ensure that their technology is not affected during extreme weather conditions. A GTMS is also useful in a laboratory situation, as the bond between the glass and metal is hermetic, the tube will be vacuum tight and so will allow you to safely pass dangerous elements through its structure.

Matched and compression seals are most commonly used in incandescent light bulbs, vacuum tubes and electric discharge tubes. Our experts have years of experience in the industrial glass manufacturing industry, no matter what your query or complaint, we can help you.

HOLLOW CATHODE LAMPS

Hollow cathode lamp bodies are made in many different configurations in diameters of 25mm, 37mm and 5Omm.

For high transmission at the UV end of the spectrum they are fabricated with special end windows such as Schott, 8337 or more commonly synthetic quartz, necessitating the incorporation of quartz-Schott 8250 graded seals in the body.

EVEN MORE EXACTING SPECIFICATIONS

For even more exacting specifications the lamp bodies can be supplied with magnesium fluoride end windows. A side window configuration in UV transmitting Kodial or synthetic quartz can also be supplied on the smaller bulbs if required.