How to Ensure Excellence in Every Glass Product

https://moores-glass.co.uk/wp-content/uploads/2024/01/clayton-cardinalli-hkJNx0EDbjE-unsplash-1024x683.jpg 1024 683 Kamran Kamran https://secure.gravatar.com/avatar/353a168c874ec096cd8e6ef9822fc7e2?s=96&d=mm&r=gIn the world of glass production, the pursuit of excellence is a universal goal for artisans and companies. This dedication is rooted in the desire to create glass products that not only meet but exceed expectations.

Practices that manufacturers follow to ensure excellence in every glass product they craft

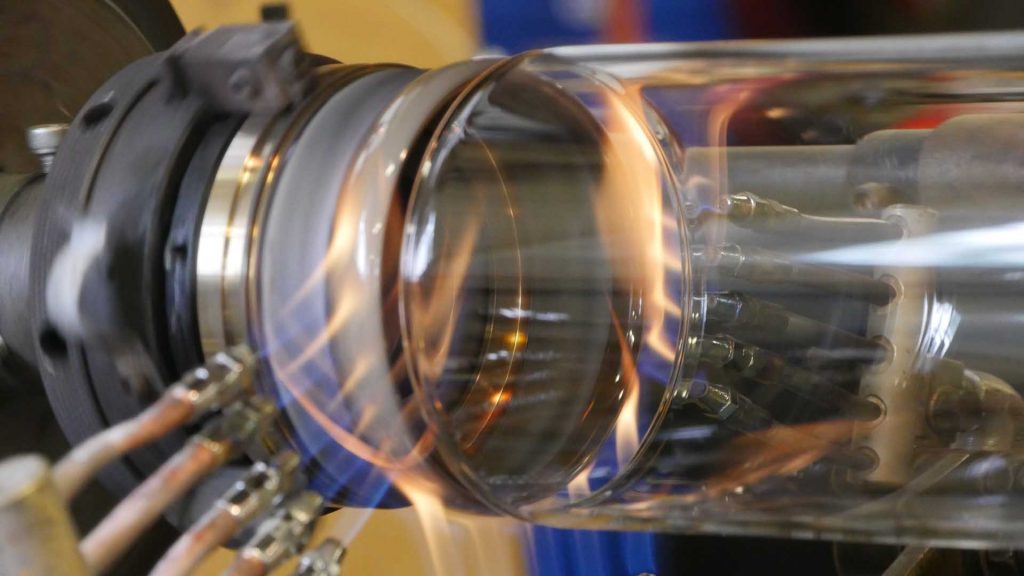

Precision in Manufacturing: From Raw Materials to Finished Product

At the core of excellence lies a dedication to precision throughout the entire manufacturing process. From sourcing high-quality raw materials to the final stages of production, maintaining rigorous standards ensures that each piece meets the exacting criteria set by the glass manufacturer.

Balancing Tradition and Innovation

Successful glass manufacturers understand the importance of blending state-of-the-art technology with time-honoured techniques, this synthesis allows for innovation while preserving the craftsmanship that defines the art of glassmaking.

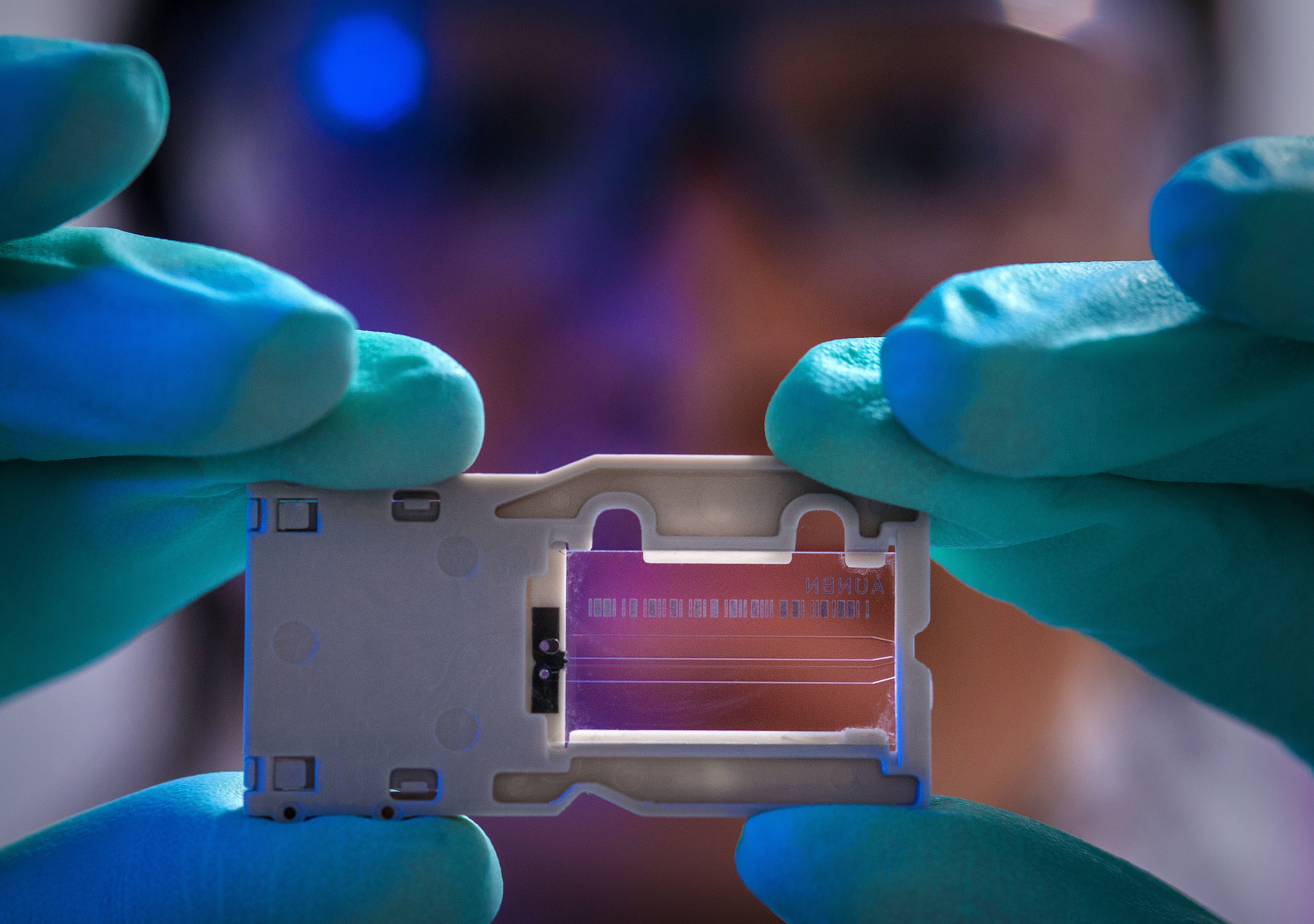

Rigorous Quality Control Measures

A commitment to excellence necessitates a thorough quality control process, each glass product undergoes meticulous inspection to ensure it not only meets industry standards but also adheres to the manufacturer’s own stringent benchmarks for quality and durability.

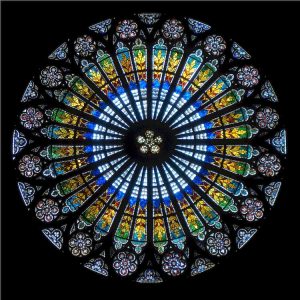

Elevating Products with a Human Touch

Behind every exceptional glass product is the expertise of skilled artisans, these craftsmen bring their experience and passion for the craft to each project, adding a layer of artistry and attention to detail that enhances the final product.

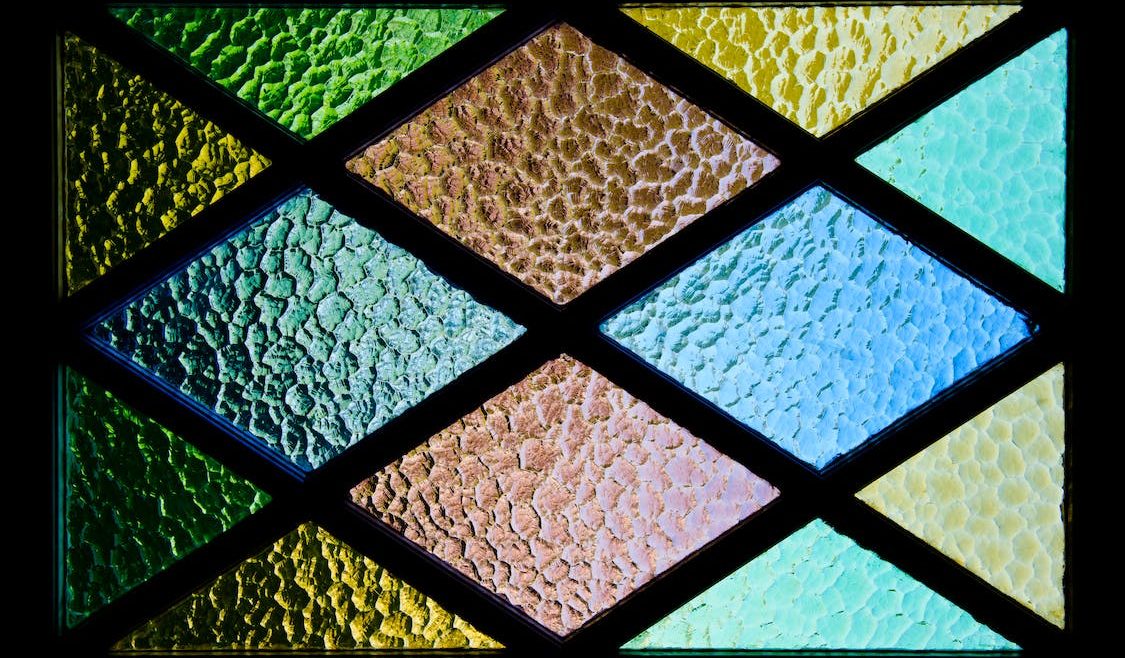

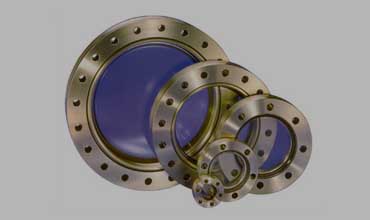

Customisation Tailored with Care

Manufacturers prioritise customisation to meet unique client specifications, whether it’s for a bespoke design or a specialised application.

An Essential Element of Excellence

Striving for excellence extends beyond the product itself to encompass responsibility for the environment. Manufacturers committed to excellence incorporate sustainable practices, using eco-friendly materials and processes that minimize environmental impact while delivering top-notch products.

Continuous Improvement and Innovation

Excellence is an ongoing journey rather than a destination. Manufacturers foster a culture of continuous improvement and innovation, always seeking ways to refine processes, enhance techniques, and push the boundaries of what is achievable in glass manufacturing.