When it comes to applications involving extreme temperatures, heat resistant glass is essential. From laboratory equipment to industrial furnaces, the right type of glass ensures safety, reliability, and performance. In this guide, we’ll explore the different types of heat resistant glass, their unique properties, and where they are most commonly used across industries.

What Is Heat Resistant Glass?

Heat resistant glass is designed to withstand high temperatures without losing strength, shape, or clarity. Unlike ordinary glass, which softens or fractures under intense heat, specialised formulations are engineered for thermal stability.

Key characteristics include:

High softening points

Resistance to thermal shock (sudden temperature changes)

Excellent optical clarity in demanding environments

Mechanical strength for long service life

Types of Heat Resistant Glass

1. Borosilicate Glass

Known for its low thermal expansion, making it resistant to cracking under sudden temperature changes.

Widely used in laboratories, cookware, and industrial equipment.

Common brand example: Pyrex™.

Temperature resistance: up to 500°C.

2. Quartz Glass (Fused Silica)

Exceptional purity and high-temperature stability.

Can withstand temperatures up to 1,200°C.

Ideal for UV applications, optics, and semiconductor manufacturing.

Offers excellent transparency across a wide wavelength spectrum.

3. Aluminosilicate Glass

Provides higher mechanical strength than borosilicate.

Temperature resistance: around 700–800°C.

Commonly used in aerospace, defence, and demanding industrial environments.

4. Glass-Ceramics

A hybrid material that combines the properties of glass with ceramics.

Offers exceptional resistance to thermal shock and extreme temperature stability.

Used in industrial furnace windows, cooktops, and aerospace applications.

Key Properties of Heat Resistant Glass

When choosing the right material, engineers and manufacturers often consider:

Thermal Shock Resistance – prevents cracking under rapid heating and cooling cycles.

Chemical Resistance – crucial for laboratory and industrial settings.

Transparency – many applications require optical clarity alongside heat resistance.

Durability – long service life reduces replacement costs in demanding systems.

Industrial Uses of Heat Resistant Glass

🔬 Scientific Research & Laboratories

Used in test tubes, beakers, flasks, and measuring equipment due to its ability to withstand repeated heating and cooling.

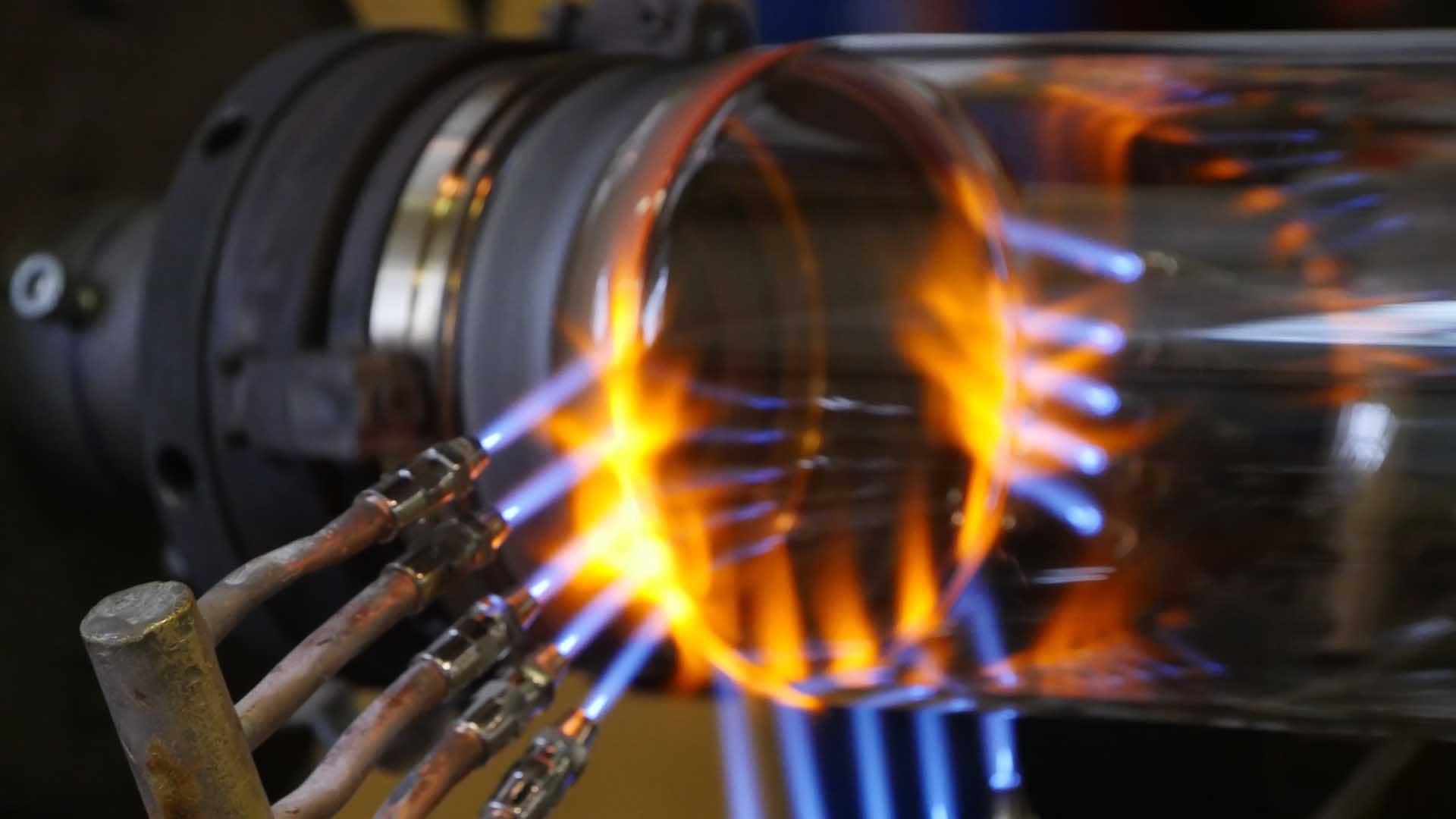

⚙️ Industrial Furnaces & Kilns

Heat resistant glass is used in viewing windows and inspection ports, ensuring safety while monitoring high-temperature processes.

💡 Electronics & Optics

Quartz glass is key in semiconductors, UV optics, and fibre optics, where heat and light intensity are critical factors.

🛫 Aerospace & Defence

Aluminosilicate and glass-ceramics provide durability in high-stress environments, from cockpit displays to missile guidance systems.

🌍 Renewable Energy

Solar panels, photovoltaic cells, and hydrogen technology use specialised heat resistant glass to ensure efficiency and longevity.

Choosing the Right Heat Resistant Glass

The correct type of glass depends on:

Maximum operating temperature

Exposure to thermal cycling

Mechanical stress and pressure requirements

Optical or chemical performance needs

Working with a specialist glass manufacturer like Moores Glass ensures you get a solution tailored to your project’s technical and commercial requirements.

Conclusion

Heat resistant glass is a critical material in industries ranging from scientific research to aerospace engineering. With types such as borosilicate, quartz, aluminosilicate, and glass-ceramics, each offering distinct advantages, selecting the right solution is essential.

At Moores Glass, we specialise in custom glass components designed for high-temperature performance, precision, and durability. Whether you need laboratory glassware, industrial furnace viewports, or bespoke engineered parts, our expertise ensures your project is built to last.

👉 Looking for heat resistant glass for your next project? Contact Moores Glass today to discuss your requirements.

Leave a Reply