As industries across the globe seek to reduce their environmental footprint, sustainable manufacturing practices have never been more important. Glass production is traditionally energy-intensive, but at Moores Glass, we are committed to minimising waste, lowering energy consumption and creating a more sustainable future for precision glass manufacturing.

Whether you are sourcing components for scientific instruments, laboratory systems or high-spec industrial equipment, understanding how your supplier approaches sustainability can help you make more responsible choices.

Why Sustainability Matters in Glass Manufacturing

Glass is an endlessly recyclable material. However, the processes involved in manufacturing technical and scientific glass components require extremely high temperatures, specialised materials and precise tolerances. Without careful management, this can result in:

High energy usage

Material waste and offcuts

Increased carbon emissions

Excess packaging and inefficient shipping

By making conscious improvements throughout the manufacturing process, Moores Glass ensures that quality is never compromised while environmental impact is reduced.

Reducing Waste in Glass Production

1. Efficient Design and Planning

Before production begins, we work with clients to create efficient designs. By optimising shapes and dimensions at the design stage, we can:

Minimise offcuts and excess trimming

Reduce material usage

Lower production time

This not only helps the planet but also makes projects more cost-effective for our customers.

2. Reusing Scrap and Offcuts

Glass offcuts created during production are not always discarded. Where possible, we reuse and repurpose materials within our processes. This significantly reduces the amount of waste leaving our workshop.

3. Smart Inventory Management

Producing only what is needed helps reduce both surplus stock and energy usage. Our made-to-order approach ensures that no glass sits idle or goes to waste.

Lowering Energy Consumption in the Workshop

Energy is essential for producing high-quality glass components, especially where melting, forming and sealing are involved. At Moores Glass, we take multiple steps to reduce energy usage across our facility:

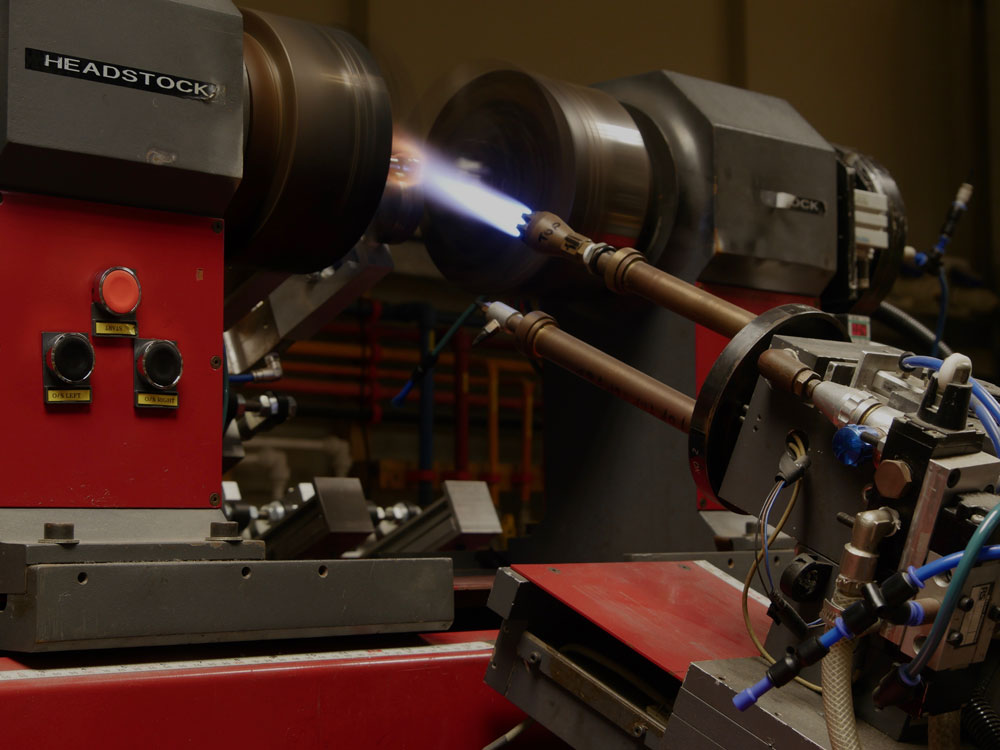

• Energy-efficient auto lathes

We invest in advanced lathes that heat glass quickly and efficiently. These systems are designed to maintain performance with less power consumption.

• Modern kilns with better insulation

Our furnaces and kilns are regularly maintained and insulated to retain heat more effectively, reducing the energy needed to reach high temperatures.

• Smarter production scheduling

By grouping similar jobs and running machines only when needed, we minimise idle time and unnecessary energy usage.

• Workplace energy awareness

Our team is trained to adopt energy-conscious behaviours, such as turning off machines when not in use and optimising heating cycles.

Eco-Conscious Packaging and Shipping

Shipping delicate glass components requires secure packaging. However, we balance this with sustainability by:

Using recyclable or biodegradable materials wherever possible

Avoiding plastic fillers unless absolutely necessary

Minimising packaging volume to reduce shipping emissions

We also work with delivery partners who align with our commitment to reducing environmental impact through efficient logistics.

Supplier Responsibility and Material Sourcing

We actively seek out suppliers who share our values. This includes sourcing:

High-purity raw materials from responsible sources

Components and seals with lower carbon footprints

Packaging materials from recycled or sustainable stocks

By choosing ethical suppliers, we support a more sustainable supply chain from start to finish.

Innovation and the Future of Green Glass Manufacturing

We continue to explore new technologies and methods to make our processes even more sustainable. These include:

Potential use of renewable energy sources

Closed-loop water cooling systems for equipment

Digital monitoring to track and reduce carbon output

As regulations tighten and demand for eco-conscious manufacturing grows, Moores Glass is ready to lead the way in sustainable precision glass production.

Frequently Asked Questions

❓ Can technical glass really be produced sustainably?

Yes. While technical glass requires significant energy to produce, modern methods and careful planning can greatly reduce its environmental impact.

❓ What are the main areas of waste in glass manufacturing?

Common areas include offcuts from forming, excess stock from overproduction, and inefficient energy use. All of these are actively managed at Moores Glass.

❓ Do sustainable practices affect the quality of the product?

Not at all. In fact, more precise and efficient practices often improve product quality while reducing waste.

Choose a More Sustainable Glass Supplier

By working with Moores Glass, you are choosing a supplier that values both precision and environmental responsibility. Whether your project requires custom borosilicate seals, vacuum viewports or quartz components, we ensure your product is created with sustainability in mind.

Contact us today to discuss how we can support your next project with environmentally responsible manufacturing.

Leave a Reply