At Moore’s Glassworks, we have a team of highly skilled professionals who are experts in glassblowing and always create stunning, bespoke products that are sure to pass our quality control tests.

But that’s not the only method we have of creating these items.

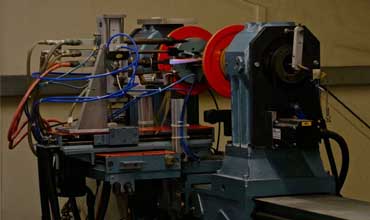

Alongside our team of glassblowers are our auto-lathe machines.

This thermographically controlled equipment is efficient and accurate and once set up, is sure to fit the brief.

We love working with our auto-lathe machines, and that’s why we’ve created this handy guide to let you know exactly what they can do, and just how they do it.

Let’s take a look.

How Does an Auto-Lathe Machine Work?

An automatic lathe is a piece of equipment that creates or adjusts products at a lightning-quick rate.

On a manual lathe, the process of moulding glass takes more time. This is because the glassblower must perform their action and then check their work, making sure it is looking as it should.

On an auto-lathe machine, the movements needed to shape the glass are done automatically, and they are carefully chosen with the help of a thermographic camera.

You may have seen these cameras being used on television or in films. This is where heat is measured through the lens, and are often seen on human bodies where you can see the warmth of the body.

The cameras on our auto-lathes are at a much smaller scale to these ones, but they are still more than capable of producing highly accurate work.

By constantly assessing the temperature and shape of the glass it is working on, the machine can decide which actions to take to best create the desired product, and all of this without any human intervention after an initial set up.

We think they’re pretty amazing, and they certainly come packed with benefits.

The Benefits of Automatic Lathe Machines in Glassblowing

Speed

This equipment is quick.

Once the profile of the product in question has been inputted, the machine can get to work, and once it begins there is no stopping it.

With the help of the thermographic camera, there is never any need to pause the building to assess the product whilst it is being created. This is because it is being continuously monitored and the results are being fed into the system automatically.

That, alongside the speed at which it can measure and evaluate the working glass, makes an auto-lathe machine a super speedy option for glassblowing.

Accuracy

Not only is an auto-lathe quick, but it is also accurate.

It always gets the product within 0.05 millimetres of the desired measurement, which means it is pretty much perfect every time.

There is also no threshold for error with our auto-lathes, and the desired results are achieved every time without fail.

Consistency

In our industry, we often encounter orders of many products that need to be in the exact same shape as all of the rest.

An automatic lathe machine makes this easy to achieve as once programmed, it is sure to keep producing an item of the exact same measurement as the previous one time and time again.

Consistency is key when producing a number of products in quick succession and this is something that is ensured with an automatic lathe.

Flexibility

No matter what project you enquire about, our machines can handle the job.

All it takes is the programming to be set up, and then the lathe equipment can get to work. This makes them an incredibly flexible machine to use and allows us to offer bespoke, and tailor-made glassblowing to businesses of all sizes and statures.

No job is ever the same, as is no customer, so it is a big positive to have equipment that can handle any request with ease.

How do you Set Up an Auto Lathe?

Surprisingly for such a complex piece of equipment, the set-up of an automatic lathe is relatively simple.

Our lathe machines come with a joystick, on which one of our skilled glassblowers can produce a piece to be used as a reference.

The automatic lathe can then read the dimensions of this piece, as well as remember the movements that had been made by the glassblower in building it, before working out the actions required to build something to the same exact dimensions.

Pushing, pulling, blowing, sealing, crushing, our lathe machines do it all, and if during the process it seems things are not looking as they should, it couldn’t be easier to reprogram the machine and make any adjustments that are needed.

A simple user interface that runs on Windows XP is also available to help even workers with little to no experience of using this equipment to be able to work it.

Once the production of this piece is complete, it is simple to switch the automatic lathe over to the next project, meaning no time is wasted in getting your products built and ready to be shipped.

Our Products

We produce many different products on our specialist equipment, including vacuum viewports, photoionization detectors, cathode ray tube glass, glass condom moulds, and more.

Due to the ease of function of these machines, we can create glass products that are fit to any size needed.

If you need a glassworks company that you know will be quick, reliable, and accurate, then look no further than Moore’s Glassworks and our auto-lathe machines.

Get in Touch with Moore’s Glassworks Today

We offer a tailor-made service, so no matter your job, get in touch with us today.

For over 40 years we have exported bespoke glass products all around the world.

From experienced glass blowers with years of glassblowing under their belt to our state-of-the-art automatic lathe machines, we can handle your job quickly and accurately.

We look forward to hearing from you.

Leave a Reply