The British glass industry contributes over £1 billion a year to the UK economy.

That’s a lot of money.

But how did it all begin?

Well, in this article, the team at Moore’s Glassworks will explore the history of glass manufacture in Britain, right from the earliest days, to the largest glassworks in the country today.

It will also look at how the glass industry has changed and what it means for the future.

Let’s take a look.

Who brought glass manufacturing to Britain?

Despite the fact that glass was manufactured in parts of Asia and Egypt for many centuries, there is little evidence to suggest that glass manufacturing actually took off in Britain until the later part of the Roman period.

In fact, most societies kept the secrets of how to make glass a closely guarded secret to try and keep the wealths this talent would bring to themselves.

The early 17th century saw a period of experimentation in the development of glass manufacturing. The early crucibles held 25kg to 50kg of glass. They were made from a fine white-firing quartz-tempered clay and were shaped in vertical or open forms.

Soon enough, as demand for glass grew, something bigger was needed.

The first glass industry in Britain was founded in Wearmouth, North of England. To begin with though, the furnaces were unstable and often broke down.

The crucibles were replaced by new, more stable designs, with later ones holding up to 85kg to 100kg of glass.

During the late 16th and early 17th centuries, glass manufacturing in Britain grew quickly. In fact, it was encouraged by government policy. Aristocratic families owned estates on both sides of the Channel and they were able to sell glass ingots to their workers.

By the middle of the eighteenth century, glass production in Britain was largely dependent on imports. It was predominantly manufactured in the Weald of Sussex and Surrey. The area was rich in coal. In addition, French glassmakers relocated to new areas where coal was abundant.

In the early 1800s, the development of a cylinder sheet process for glass-making increased the volume and quality of British glass. In addition, the window tax was abolished, and prices of glass were greatly reduced. The cylinder sheet process was imported from Germany in 1834.

In the mid-1800s, a number of sites were identified in the Weald, including the site of an early glassworks at Arras. Some sites were excavated in the 1960s, but there is also evidence that there are other unrecorded locations.

The first glassworks in Britain

By the seventh century, glass was being made in Jarrow and Wearmouth. At the same time, a team of glassmakers from Gaul was working at Glastonbury. These migrant workers were using their knowledge of the continent to produce quality glass in England.

In the late 16th century, the glass industry in England received a major stimulus. The new furnace technology reduced the cost of making glass, and the new materials allowed for the creation of higher quality English glass.

In the post-Restoration period, glassmakers tried to replace the variable composition of the earlier period with more carefully measured fluxes. They also began to apply for a series of patents. They hoped to create a more solid, clear glass.

During the seventeenth century, the glass industry expanded dramatically. The government encouraged immigrants to work in the industry. Several migrant families were based in established glassmaking centres in the Weald.

By the early nineteenth century, the Chance Brothers’ glassworks in Smethwick, West Midlands, was producing window glass and optical glass. They also produced Houses of Parliament window glass.

The Stourbridge glassmaking industry became one of the largest in the western world, and its engineers spread to the New World. The industry was considered among the best in the world.

The Biggest Glassworks in Britain

Historically, the biggest glassworks in Britain were situated in the North East, Yorkshire, Staffordshire, the Midlands and London. The British glass scene has changed a great deal since the 19th century, but there are still a few surviving structures. In the 20th century, studio glass started to grow in popularity.

The British glass industry is a resilient one, thanks to a high demand for glass. In the 21st century, data indicates that the UK’s glass industry produces the most glass for food packaging in the world.

In the eighteenth century, the Weald of Sussex and the Weald of Surrey were well established domestic glass production centres. The Catcliffe Glasshouse, built in 1740, is the oldest surviving structure of its kind in Western Europe. The cone is now a museum.

In the early nineteenth century, the Chance Brothers glassworks was established in Smethwick, West Midlands. They made a range of specialist glass for use at Crystal Palace. They were also the first factory in Britain to produce glass for the Houses of Parliament. This is a Grade II listed building. They also produced glass for the 1851 Great Exhibition.

There were three giant glass companies in the North East during the nineteenth century. Burtles Tate & Company operated a glassworks near Oldham Road, Manchester. They produced Topas Opalescent glass. They also produced bottles and novelties.

Another renowned glassmaker, John Derbyshire, set up a Flint Glass Works in Salford. His designs are famous. They often feature JD initials on either side of an anchor. He also set up the Regent Road Flint Glass Works in Salford in 1873. He was succeeded by his brother James Derbyshire.

In modern times, the technology and tools at hand have improved dramatically, meaning that glass manufacturing plants can create identical bulk products in a fraction of the time. The ease of exporting has also made the British glass industry able to ship across the world with ease.

Moore’s Glassworks

There are still an abundance of glassworks throughout Britain, and there’s a reason for that.

Glass is everywhere you look.

In your car, your home, even balanced on your nose helping you to read this.

Many glass manufacturers produce different types of glass aimed at different markets and products.

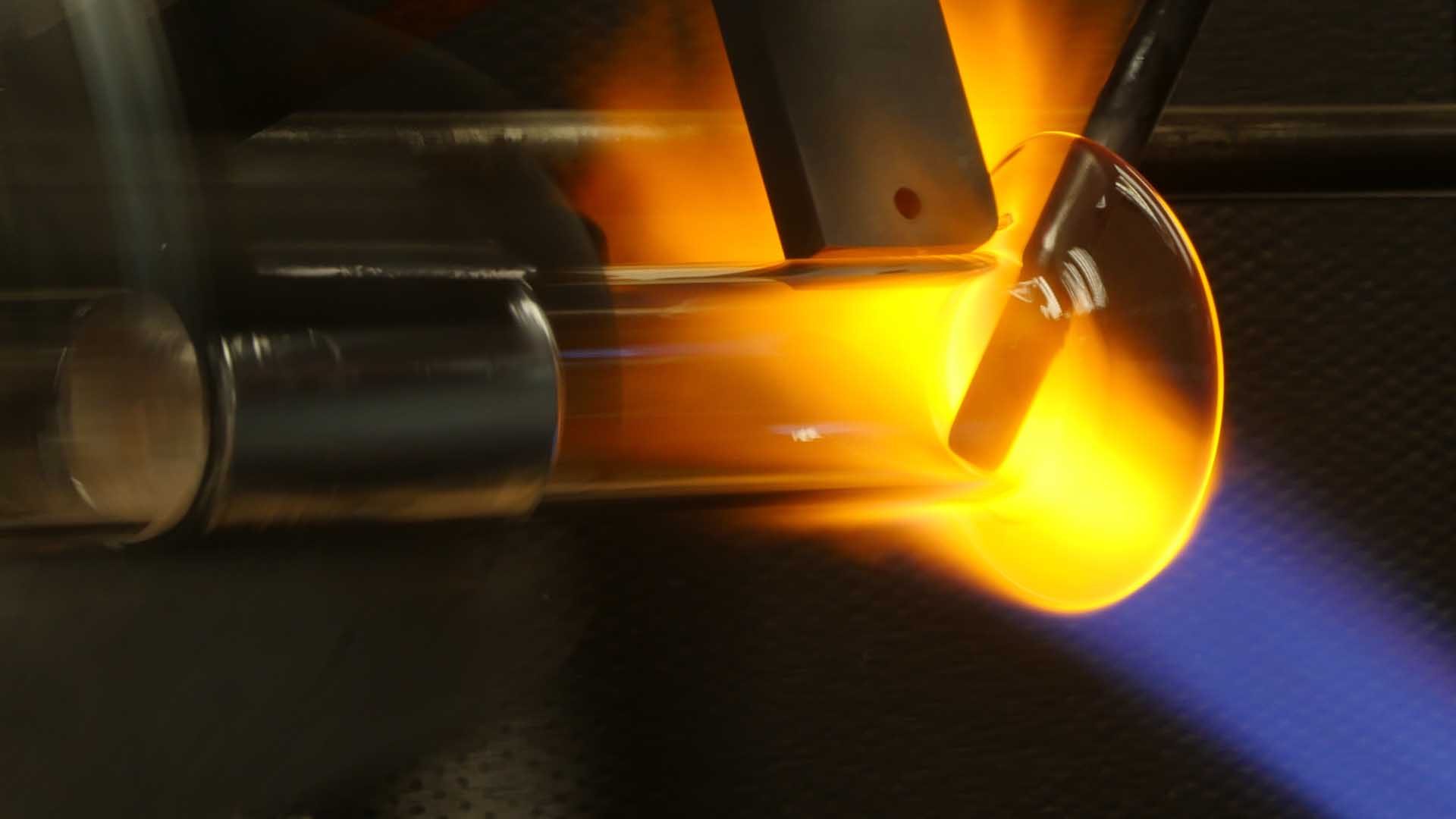

For example, here at Moore’s Glassworks, we specialise in custom products such as vacuum viewports, cathode ray tubes, glass condom moulds, and multi-pin stems and headers.

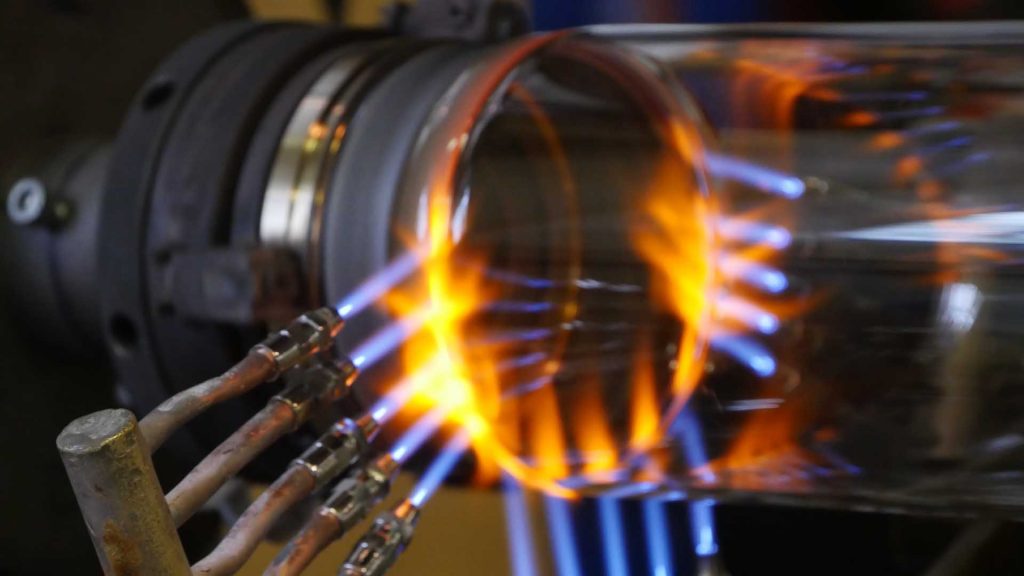

We use auto lathes to produce products that are just the right dimension for you, and ensure every product we create is of the highest quality.

If you would like to know more, then get in touch today.

Leave a Reply