Glass, with its timeless beauty and diverse applications, is a material that demands precision and perfection.

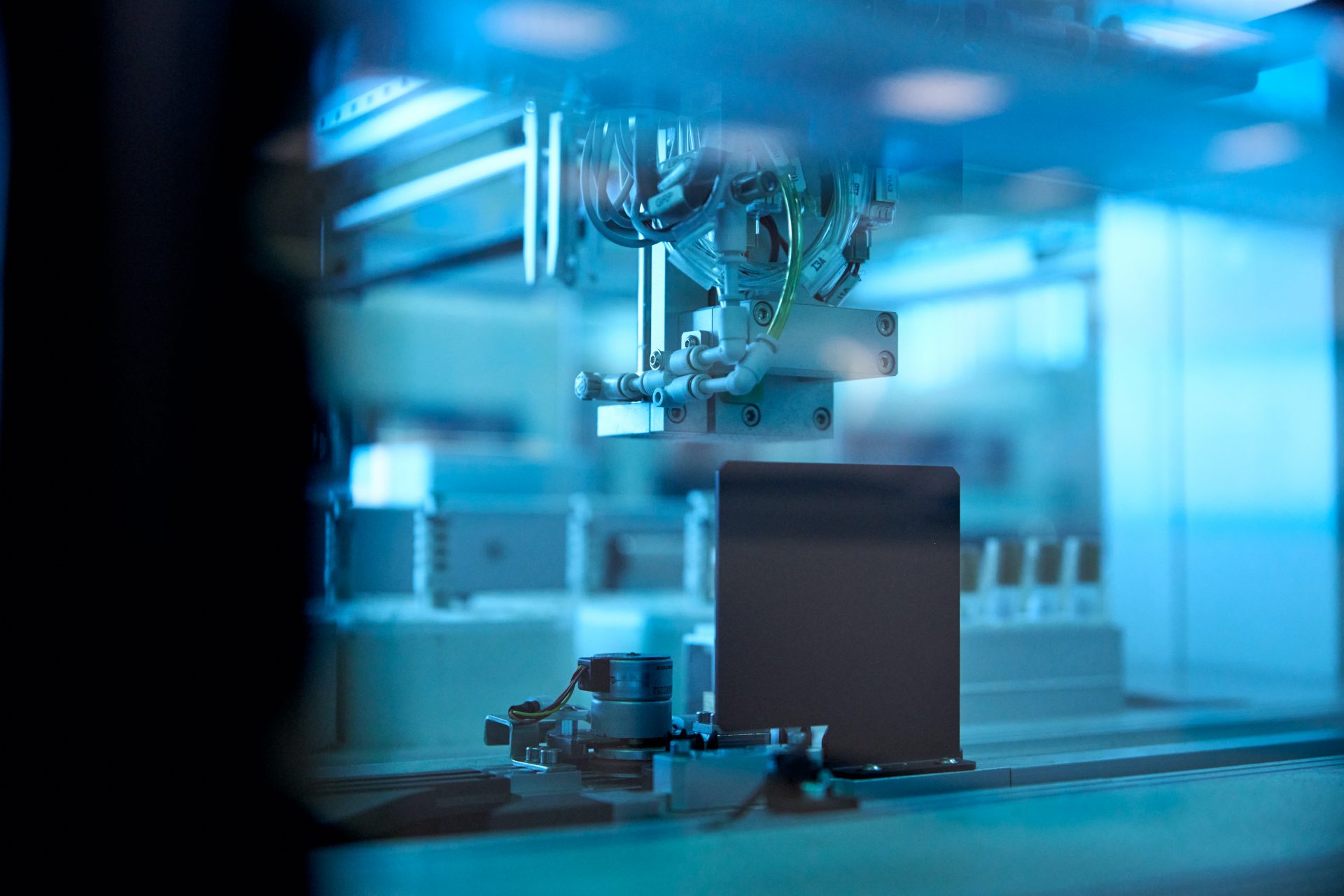

Behind every stunning glass creation lies a meticulous process of design, manufacturing, and, perhaps most importantly, quality control.

In this blog post, we delve into the critical role that quality control plays in the realm of British glassworks craftsmanship, highlighting its impact on the end product’s performance, aesthetics, and overall customer satisfaction.

Understanding the Significance of Quality Control in Glassworks

Quality control is an integral part of the British glassworks craftsmanship, it is not just a routine checkpoint, but a comprehensive system that ensures that each piece meets the highest standards.

This process includes various stages of production, ranging from the inspection of raw materials to the final inspection conducted before delivering the product to the customer.

Raw Material Inspection for Glassworks

Quality control is a crucial part of the manufacturing process, and it begins with the raw materials. Glass manufacturers check the quality of these materials before starting production to identify and address potential issues early on.

This stage involves scrutinising the raw materials for impurities, consistency in composition, and ensuring that they meet the required specifications for the intended use.

Manufacturing Process in Glassworks

Once production is underway, quality control measures continue at each step, this involves monitoring factors such as temperature, pressure, and timing to guarantee that the glasswork is formed with precision and accuracy.

Any deviations from the established parameters are identified and corrected promptly to maintain the desired quality.

Appearance and Finishing in Glassworks

Quality control teams focus on evaluating the glass for imperfections, clarity, and uniformity in colour and texture. This step ensures that the finished product not only meets functional requirements but also exceeds expectations in terms of aesthetics.

Testing for Strength and Durability in Glassworks

Glass works often serve structural or functional purposes, and as such, their strength and durability are paramount.

Quality control measures include rigorous testing for impact resistance, load-bearing capabilities, and thermal performance, this ensures that the glasswork can withstand the challenges of its intended use without compromising safety or longevity.

Batch-to-Batch Quality Assurance in Glassworks

Maintaining consistency across batches is a hallmark of reliable British glassworks craftsmanship. Quality control processes extend to routine checks and assessments, guaranteeing that each batch adheres to the established standards. This commitment to consistency is essential for architects, builders, and clients who rely on uniformity in their projects.

Final Inspection and Assurance in Glassworks

The last line of defence in quality control is the final inspection before products leave the manufacturing facility. This thorough assessment ensures that every piece of glasswork meets the predefined criteria for excellence. By delivering a flawless product, manufacturers instil confidence in their customers, building trust and loyalty.

Elevating Standards, Ensuring Satisfaction in British Glassworks Craftsmanship

In the dynamic world of British glassworks craftsmanship, where form meets function, quality control stands as the guardian of excellence.

By meticulously overseeing every aspect of production, from raw materials to the finished product, manufacturers not only meet industry standards but exceed them. In doing so, they deliver glass works that captivate with their beauty, endure with their strength, and, above all, satisfy the expectations of clients and consumers alike.

Moore’s Glassworks

The UK’s role in the global glass manufacturing industry is undeniably significant.

Its historical contributions, manufacturing clusters, and centers of excellence, along with its commitment to innovation, sustainability, and design, have positioned the country as a key player on the international stage.

As the industry continues to evolve, the UK’s expertise, craftsmanship, and technological advancements will continue to shape the future of glass manufacturing globally.

Here at Moore’s Glassworks, we are a UK-based bespoke glass manufacturer and we are proud of the role we play in creating high-quality glass products for specialist uses that are used throughout the world.

Whether manufactured on our auto-lathe or at the hands of one of our experience and talented glass blowers, we always create a product fit for use and in great condition.

Want to know more? Or want to discuss a project with us? Then get in touch with our team today.

Leave a Reply