January 2026: Why Quality Control Matters: Ensuring Precision and Reliability in Custom Glass Manufacturing

https://moores-glass.co.uk/wp-content/uploads/2018/07/Quality-Control-.jpg 570 320 Matthew Morris Matthew Morris https://secure.gravatar.com/avatar/09048644f0c2340325fc98c2460d4a4f?s=96&d=mm&r=gIntroduction

Quality control is foundational to excellent custom glass manufacturing. In an industry where precision and reliability are essential, ensuring that every product meets exacting standards is not optional. At Moores Glassworks Ltd, we recognise that meticulous quality control not only protects the integrity of the glass components we produce but also underpins the confidence our clients place in us. With nearly four decades of experience as a UK-based custom glass manufacturer, we have developed a reputation for quality and performance that supports customers in scientific research, industrial applications and bespoke engineering challenges worldwide. Our approach to quality control is built into every stage of our manufacturing process and contributes directly to the precision and dependability of our products.

Glass products used in specialised applications must be dimensionally accurate, free from defects and capable of performing reliably under stress. Whether clients require vacuum viewports, cathode ray tube envelopes or multi-pin bases, the demands placed on these components are high. Our quality control philosophy ensures that every item we supply is thoroughly inspected and approved before dispatch or storage. This commitment to quality contributes to the continued success of our business and reinforces our position as a leader in custom glass solutions.

Why Quality Control Matters in Custom Glass Manufacturing

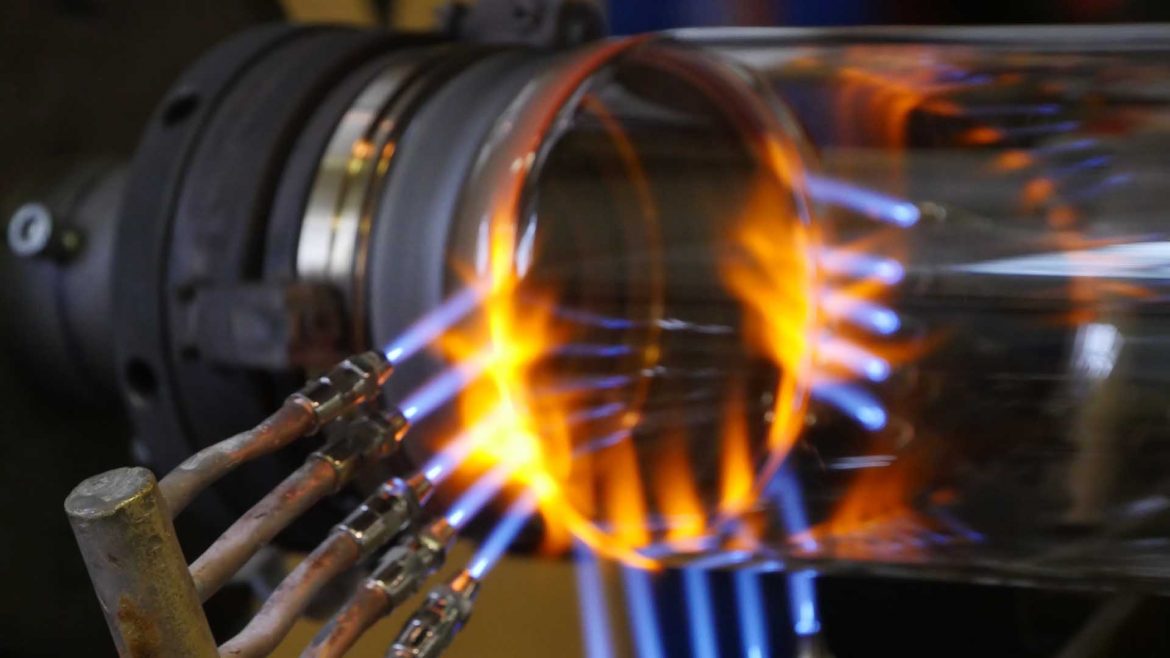

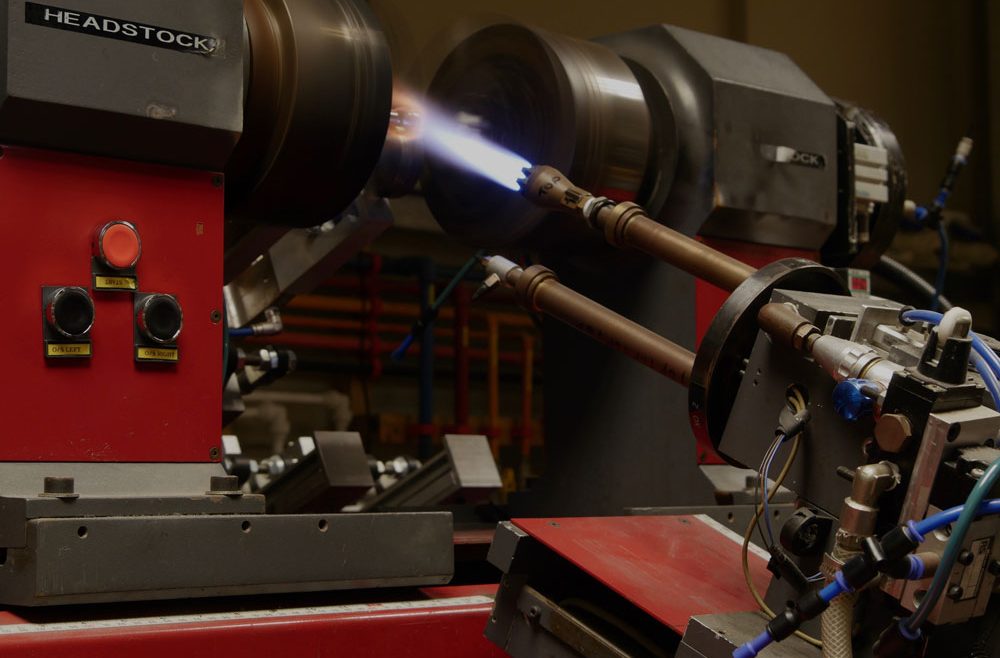

Quality control matters because glass manufacturing for specialised applications often involves bespoke designs where even minor variations can lead to failure in the field. At Moores Glassworks, quality control is a core process that enables us to detect and eliminate any problems with glassware products before they reach our customers. Human skill remains central to our operations as many of our products are crafted by specialist glassblowers. Although we also use automated lathes where suitable, the careful inspection by experienced technicians ensures that the human aspect of craftsmanship is preserved and quality is not compromised.

Ensuring precision in custom glass parts requires more than checking dimensions. It is about understanding the function of each component and assessing whether it will perform as intended in its application. A viewport used in a high vacuum chamber for scientific experiments must maintain integrity under pressure and thermal variation. A photomultiplier envelope must preserve optical clarity while sustaining structural strength. In each case, quality control ensures that these functions are realised consistently. By thoroughly inspecting each piece, our quality control team prevents defects from being dispatched and safeguards the standard of excellence associated with Moores Glassworks products.

Precision matters at every stage of manufacturing. From the moment raw materials are selected through shaping and forming to final inspection, every factor that could influence the performance of the component is considered. This methodology ensures that our bespoke glass components meet the needs of clients who often operate in environments where reliability is critical. Quality control is therefore not an add-on but an indispensable part of how we manufacture glass products that perform with precision and dependability.

What Quality Control Looks Like in Practice

At Moores Glassworks, quality control manifests in a series of deliberate and careful inspections. Our glassware products are inspected by our quality control team before being dispatched or stored. This enables us to discover and correct any issues before products leave our facility. Where automatic lathes are used for fabrication, their output is still subject to the same rigorous checks that govern handcrafted items. Human inspection remains central because many bespoke products require adjustments that only skilled eyes can verify and confirm.

Meticulous inspection covers visual assessment, dimension verification and functional evaluation. Visual assessment ensures that there are no surface imperfections, bubbles, cracks or other defects that could compromise the item. Dimension verification confirms that the item matches the specification provided by the customer. Functional evaluation considers the intended application of the component and verifies that it will perform reliably in service. This approach enables us to maintain the highest standards and mitigate risks associated with defects or deviations from specifications.

Our quality control process ensures that custom glass components are built to exact requirements. This is especially important for products like vacuum viewports, which must integrate within sealed systems and support conditions that can include temperature and pressure variations. By focusing on quality at every stage, our team ensures that the final product meets the performance expectations of our clients.

Case Example: Precision Components That Demand Quality

Vacuum viewports are a clear example of why quality control matters. These products are fabricated in a range of sizes and are made from specialised glass materials that support thermal stability and optical clarity. Quality control in the manufacturing of vacuum viewports involves careful inspection of the glass and the seals that maintain vacuum integrity. If the seal does not meet specification, then the entire system could be compromised. Our team ensures that each viewport meets the exact specification required and is capable of maintaining the conditions necessary for reliable operation.

Similarly, photomultiplier envelopes require exacting standards because they operate in scientific instruments where even minor imperfections can influence measurement accuracy. Ensuring that these envelopes are manufactured to uniform standards and are free from defects is essential. Our quality control checks ascertain that each envelope meets the precise requirements for dimension and performance.

Multi-pin bases and PH electrode glass bodies are additional examples of bespoke components where precision is essential. These products are often used in specialised industrial and scientific applications where any deviation could result in malfunction. Our approach to quality control ensures that each item is produced with the accuracy and reliability expected by our clients.

By applying rigorous quality control across all products, we ensure that each bespoke piece of glasswork meets its intended purpose. This consistency underwrites our reputation for delivering custom glass solutions that clients can trust.

How Skilled Teams and Technology Support Quality

Quality control does not exist in isolation but is supported by the combination of skilled personnel and appropriate technology. At Moores Glassworks, our team includes highly skilled engineers, designers and specialist glassworkers. Their collective expertise enables us to interpret specifications accurately and translate them into high-quality products. Human skill is essential when evaluating bespoke products that may require nuanced judgment beyond what automated systems can provide.

Despite the importance of human expertise, we also utilise advanced technology to aid precision. Automated lathes play a role in producing accurate and repeatable glass components. The integration of precision machinery helps us achieve consistent outcomes and allows us to meet tight deadlines. However, we always ensure that products manufactured using technology are subject to the same quality control standards as hand-produced items.

The balance between skilled teams and technology creates an environment where quality is enhanced by both human insight and mechanical precision. This collaboration enables us to consistently deliver products that meet stringent specifications while supporting the custom nature of each order.

Benefits of Strong Quality Control for Customers

Strong quality control yields several benefits for our customers. Reliability is the most significant advantage because clients can trust that products will perform as intended when installed. Glass components such as vacuum viewports and photomultiplier envelopes often operate within complex systems where failure is not an option. Quality control ensures that these components are dependable and capable of withstanding the conditions in which they are used.

Safety is another benefit of rigorous quality control. In many industrial and laboratory environments, glass components are exposed to pressure, temperature variation and chemical exposure. Ensuring that glass products are free from defects and manufactured to specification reduces the risk of failures that could pose safety hazards.

Longevity is also enhanced when products are manufactured to high standards. Custom glass components that have passed rigorous inspection are more likely to withstand continued use without degradation. This durability supports long-term performance and reduces the need for premature replacement.

Finally, quality control contributes to the custom fit of bespoke glasswork. Clients benefit from components that are made exactly to specification. This exactness ensures that the product integrates seamlessly into its application and performs reliably.

Conclusion: Quality Control as a Competitive Advantage

Quality control is fundamental to custom glass manufacturing. At Moores Glassworks Ltd, it is integrated into every part of our process and ensures that products are produced with precision and reliability. Our commitment to quality supports our reputation for excellence and assures clients that each bespoke glass component will fulfil its intended purpose. Strong quality control builds trust, enhances performance and contributes to customer satisfaction. As we continue into 2026, our dedication to quality control remains a cornerstone of our work and a competitive advantage that sets us apart in the industry.