5 Key Industries in Which Our Products Can be Used

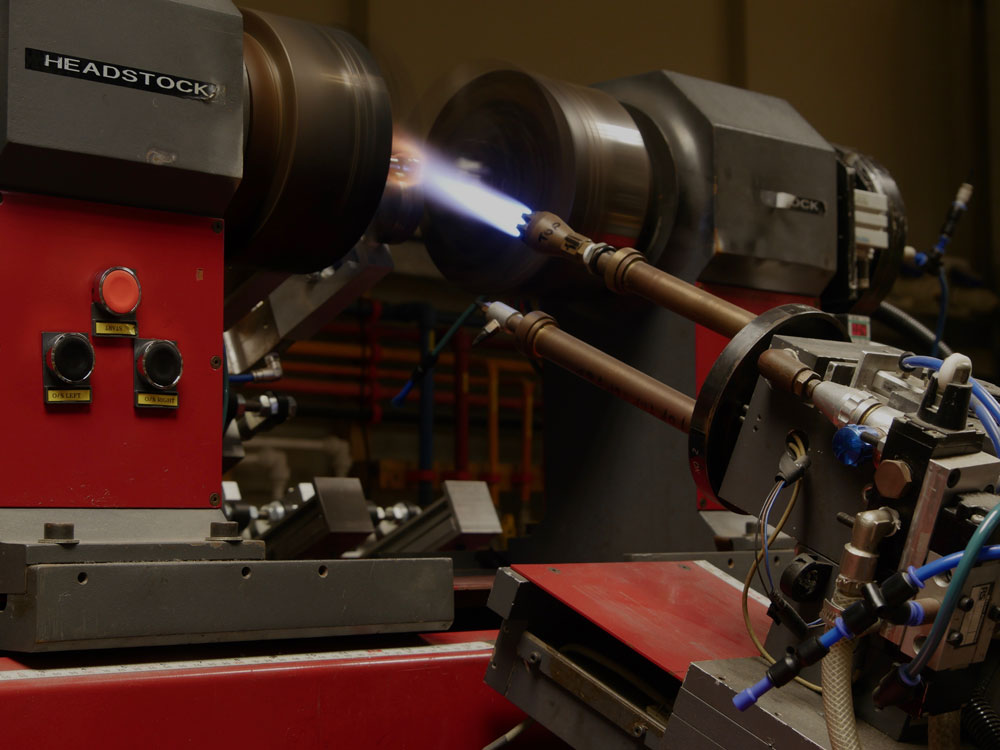

https://moores-glass.co.uk/wp-content/uploads/2024/02/PH-electode-Made-on-auto-lathes--1024x472.jpg 1024 472 Matthew Morris Matthew Morris https://secure.gravatar.com/avatar/09048644f0c2340325fc98c2460d4a4f?s=96&d=mm&r=gIn an era where technology and science continue to break boundaries, certain specialised glass products have begun to play pivotal roles in various critical settings.

Among these are some of the products manufactured right here at Moores Glassworks, standing out for their versatility and indispensability.

These components, though often hidden from the public eye, are essential in many different industries, environments, and applications.

Understanding the diverse uses for our products not only highlights their importance but also underscores the technological advancements they facilitate.

We’ve created this guide to tell you more.

5 Industries Where Our Products Thrive

Military Applications

The military sector demands precision, reliability, and cutting-edge technology to ensure the safety and effectiveness of its operations.

Vacuum viewports and cathode ray tubes serve as critical components in this high-stakes environment.

Vacuum viewports, for instance, are integral to night vision equipment, enabling soldiers to operate in low-light conditions with enhanced visibility.

Cathode ray tubes, although considered a technology of the past in consumer electronics, still find relevance in military displays due to their durability and reliability in extreme conditions.

These components contribute significantly to the military’s capabilities, from secure communications systems that rely on the clear transmission of information to navigation displays in aircraft and ships, ensuring precise movements in complex operations.

The integration of these technologies into military equipment exemplifies their impact on operational effectiveness and the safety of personnel.

Scientific Research and Laboratories

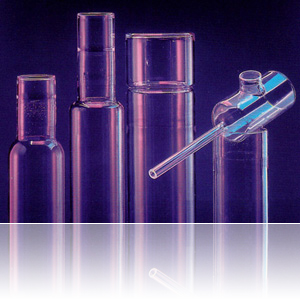

In the realm of scientific research, photomultiplier envelopes, photoionization detectors, and vacuum viewports are indispensable tools that propel the boundaries of knowledge.

Photomultiplier tubes, encased in envelopes, are crucial in experiments that require the detection of low levels of light, such as in particle physics and astronomy. They amplify the signals from photons to measurable levels, enabling scientists to observe phenomena that would otherwise be invisible.

Photoionization detectors play a pivotal role in environmental science and chemistry, where detecting and measuring the concentration of volatile organic compounds (VOCs) is essential.

These detectors facilitate air quality monitoring and the study of atmospheric chemistry, contributing to our understanding of pollution and its effects on climate change, and here at Moore’s Glassworks, we specialise in building glass bodies for this equipment.

Vacuum viewports, with their ability to maintain a vacuum while providing visual access, are invaluable in laboratory experiments that require observation under controlled atmospheric conditions.

They are used in a wide range of scientific applications, from electron microscopy to high-energy physics experiments, where maintaining a pristine environment is critical.

Industrial Use

In the industrial sector, cathode envelopes and photoionization detectors are fundamental to maintaining efficiency, quality, and safety.

Cathode envelopes, used in cathode ray tubes, find applications in the visualisation of processes in control rooms and for monitoring equipment status, contributing to the smooth operation of manufacturing processes.

Photoionization detectors, on the other hand, are essential for ensuring workplace safety, especially in industries dealing with chemicals and hazardous substances.

They provide real-time monitoring of toxic vapours, allowing for immediate action to prevent exposure and mitigate risks.

These technologies not only enhance operational efficiency but also play a critical role in protecting workers and the environment.

Electronics and Technology

The electronics and technology sector continues to evolve at a rapid pace, with cathode ray tubes and vacuum viewports playing key roles in its development.

Despite the widespread adoption of LCD and OLED displays, cathode ray tubes find niche applications in specialised electronics where their robustness and unique display characteristics are preferred.

Vacuum viewports facilitate the development and testing of electronic devices under vacuum conditions, crucial for semiconductor manufacturing and research.

They enable precise control and observation of processes at the molecular level, ensuring the high quality and reliability of electronic components.

These products not only contribute to the advancement of consumer electronics but also support the research and development activities that drive innovation in the technology sector.

Aerospace Exploration

Aerospace exploration, a field that embodies human ambition and ingenuity, relies on photomultiplier envelopes and vacuum viewports to push the boundaries of our knowledge and capabilities.

In the harsh environment of space, photomultiplier tubes are used as instruments that study celestial phenomena, from analysing the composition of distant stars to detecting cosmic rays.

Vacuum viewports play a crucial role in the testing and observation of space-bound equipment, ensuring that they can withstand the vacuum of space.

These components are essential for the success of satellite technology and space exploration missions, enabling research that increases our understanding of the universe and improves communication technologies on Earth.

Specialist Glass Manufacturing from Moore’s Glassworks

All of these products are more than just components; they are the building blocks of modern technology and science.

Their applications across the various sectors mentioned throughout this blog demonstrate their versatility and the critical role they play in advancing human knowledge and capability.

As technology continues to evolve, the importance of these products in enabling innovation and ensuring safety and efficiency in various applications cannot be overstated.

Here at Moore’s Glassworks, our team are proud to work across many different industries, providing glass products that are fit for purpose and built to last.

If you want to know more, then get in touch today.