The Importance of Precision in Our Custom Glass Product Manufacturing

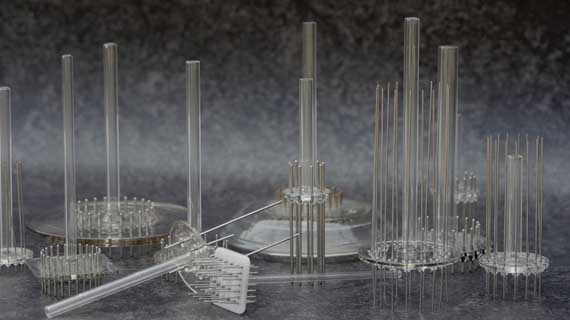

https://moores-glass.co.uk/wp-content/uploads/2024/04/x-ray-tubes-1024x683.jpg 1024 683 Matthew Morris Matthew Morris https://secure.gravatar.com/avatar/09048644f0c2340325fc98c2460d4a4f?s=96&d=mm&r=gImagine a world where every piece of glass in your home, car, or office was just slightly off in size or thickness.

Your windows might not quite fit, your glasses might easily break, or your car’s windshield might not be as sturdy. This is why precision is paramount in custom glass product manufacturing. In industries where the margin for error is nearly zero, such as many that we produce products for here at Moore’s Glassworks, achieving flawless precision ensures not only the functionality but also the safety and aesthetics of the final product.

Whether it’s our cathode ray tubes, or our vacuum viewports, working to exact measurements is something every skilled glass engineer in our team is trained in.

We’ve created this blog to tell you more, so let’s take a look.

Precision in Glass Manufacturing

Precision, in the context of manufacturing, refers to the exactness and accuracy with which products are made according to specifications.

In glass manufacturing, this precision affects everything from the thickness and cut of the glass to the consistency of its composition. Given that glass is both a functional and decorative material used in a multitude of applications—from architectural designs to everyday utensils—its production tolerances are often incredibly tight.

In bespoke glass manufacturing, every product may be needed to adhere to different specifications and the tiniest millimetre of error can lead to big issues.

This is why precision is such an important factor in this process, and only exact fittings will suffice.

Challenges of Achieving Precision

Achieving these high levels of precision isn’t easy though, and there are challenges:

- Material Challenges: Glass is inherently a brittle material, prone to breaking and chipping if not handled or processed correctly. Variations in temperature during production can also lead to inconsistencies in strength and clarity, making the manufacturing process a delicate science. When achieving precision, you must be able to handle glass as it is being sculpted and ensure it fits the measurements perfectly.

- Technological Constraints: The technology available in glass manufacturing, such as kilns and cutting tools, imposes limitations. Older machines or poorly maintained equipment can result in production errors that are often costly to correct. Here at Moore’s Glassworks, we don’t have these issues, as our state-of-the-art auto lathes are ideal for creating glass products that are as precise as can be.

- Human Factors: The human element in glass manufacturing is vital, but can lead to errors. Skilled artisans can craft extraordinary pieces with precision that machines cannot match, but human error remains a risk. Training and continuous skill development are crucial to minimising these errors.

Benefits of High Precision

Product Quality

Highly precise glass manufacturing leads to products that are not only visually appealing but also more durable and better performing.

For instance, in terms of vacuum viewports, these have to fit the exact measurements or else they will not work to their full capabilities and could be damaged when put into the high pressure situations they are made for.

Customer Satisfaction

When products meet or exceed expectations in terms of quality and performance, customer satisfaction naturally follows.

This can lead to repeat business, referrals, and a strong reputation in a competitive market.

We take pride in producing great products for every client, no matter the size or shape of the job, and that’s why we deliver products across the world to happy customers.

Compliance and Safety

In many uses of glass, from automotive to architectural, safety standards must be rigorously met.

Precision ensures compliance with these standards, protecting manufacturers from legal repercussions and protecting consumers from potential harm. The smallest error in precision can lead to issues in terms of safety, especially when in situations that may contain radiation, for example.

This is why precision is so vital and every product must be rigorously checked to ensure it is safe to perform it’s intended tasks.

The Future of Precision in Glass Manufacturing

Looking forward, the integration of AI and IoT into glass manufacturing promises even greater levels of precision. These technologies can help predict and adjust for variability in material properties and environmental conditions in real-time.

It is also important to keep a close eye on consumer trends, and trends in the industry, as these can pave the way for new methods and equipment that can help improve precision and create better products.

As consumer and regulatory demands for safety and quality continue to rise, the industry is likely to see an increased emphasis on precision. This will drive further innovations and improvements in manufacturing technologies and techniques and here at Moore’s Glassworks, we plan on always staying on top of the latest updates.

Our Auto Lathes

Auto lathes significantly enhance precision in glass manufacturing, merging the artistry of traditional glassblowing with advanced automation technology. Operated remotely using controls like joysticks, these machines allow glassblowers to create a reference piece during a process known as acquisition, where every action and its effects are recorded. The machine’s software analyses this data to generate a production program, which can be adjusted for quality improvements or specific production needs.

Unlike manual methods, auto lathes operate under a closed-loop system, where embedded thermographic cameras continuously monitor and adapt to the temperature and dimensions of the glass. This ensures adjustments are made in real-time to accommodate variations in material properties or environmental conditions. With the ability to maintain precision up to ±0.05 millimeter, auto lathes surpass the accuracy achievable by human hands, offering superior consistency and repeatability in production.

This technology not only replicates the manual skills of glassblowers but enhances them, providing a reliable solution for large-scale productions where consistency and precision are paramount. Auto lathes represent a leap forward in glass manufacturing, setting new standards for quality and efficiency in the industry.

Conclusion

The relentless pursuit of precision in the manufacturing of custom glass products is not just about adhering to specifications; it’s about exceeding them to deliver products that enhance safety, performance, and aesthetics.

Here at Moore’s Glassworks, our products are always precise to the exact measurements requested by our clients.

Want to know more? Then get in touch with our team today.