We send our glass products all over the world.

For every customer that we ship an item to, we hope that they are happy with their purchase, and that the glass product in question does it’s job as it should and lasts for a long time.

Every time we manufacture one of our glass items, we take the utmost care to ensure it is of the highest quality, and that is durable and up for the task at hand.

But there are ways our customers can help to increase the lifespan of their purchase, including these ten tips.

Let’s take a look.

10 Tips on Caring for Your Glass

Handle with Care

The first hint in this guide relates to all glass products, and it is that you must be careful when handling and transporting your glass products.

One of the biggest causes of damage to glass products is people dropping them or banging them as they hold them. This is a big issue as if glass smashes whilst you’re holding it, it can be dangerous for you.

Make sure you are extra careful every time you hold glass, wearing gloves if needed, and always having a clear path ahead of you without any trip hazards.

Store Properly

The location that you store your glass is important for it’s longevity.

There are two key features of your glass storage, and they are that is should be dry, and it should be cool.

Your glass should never be kept in direct sunlight or an environment that is humid as this can cause issues with your product.

Also, make sure you are storing it on a soft surface to avoid scratching and try not to overfill your storage and pile products on top of each other as this could lead to pressure which may cause a break.

Keep it Clean

If you can keep your glass clean, then the clarity you need for the glass to function properly should remain throughout the lifespan of the product.

This is especially important in some of our products such as vacuum viewports and cathode ray tubes.

Avoid using rough cleaners such as brushes that are too hard, and try to keep away from chemicals.

In most cases, a soft cloth will do the trick.

If you can regularly clean your glass, then you will always have an item that looks in perfect condition and works just as it should.

Make Sure it is Well Dried

On the topic of cleaning.

If you are using water or a cleaning substance to keep your glass in great condition, then you must make sure it is completely dried before you use it again or place it in storage.

If water is left on your glass, then this can lead to water spots which can be detrimental to the visibility of your item.

Also, cleaning solutions may leave marks or damage the glass, so this must also be wiped off.

Again, try to avoid using a harsh material to do this, and use a soft cloth if available to eliminate the risk of scratching.

Handle Different Components Carefully

Every glass item manufactured at Moore’s Glassworks has passed our strict quality control and is always right for the job at hand.

If you are attaching it to your equipment, or using it, then it may come into contact with other components.

It is important that you handle these carefully, making sure you don’t bang them together and that any attachments aren’t too tight and therefore putting a strain on the glass.

If your glass item has a lid or a cap for example, or has smaller components that require special attention, make sure they are handled correctly and that everything is secure and in place before use, especially when dealing with potentially hazardous materials.

Use Heat in the Right Way

Glass and extreme temperature don’t always mix. In fact, some thinner glasses can only withstand heat of around 160 degrees Celsius.

It is also hazardous when glass goes through a quick temperature change.

A good example of this is the warning not to pour boiling water on a frozen car windscreen as the change in temperature may cause the glass to crack.

While a lot of our products use glass that is designed and manufactured to be able to withstand extreme temperature and pressure, this isn’t always the case, so always be careful when dealing with these situations and make sure your glass is up for the test before adding in the hot or cold component.

Keep an Eye Out for Damage

Constantly checking your glass for damage is important.

A small crack in a glass product can lead to bigger issues if left unattended. Regularly checking your glass (it is a good idea to do this while cleaning) will ensure that it is always in working condition and that any issues can be quickly rectified before they cause major problems.

Glass can be damaged in many ways, as we have mentioned throughout this blog, so it is vital that you assess the condition of it when it arrives to check for transportation damage, and also after handling it, or after it has been under high pressure.

It is also a good idea to always check it before use, especially if dealing with high pressure situations, as this will give you assurance that it is up to the task and won’t pick up any major damage.

Try Not to Stack

We’ve already touched on storage, but this is another important point that is definitely worth highlighting.

When placing your products in storage, try not to place glass items together somewhere they may rub.

This applies to when transporting your items as well. When glass comes into contact with a similar material, it can cause scratching and in some cases cracks so you must be careful to not place them together.

If you have no other choice, try to place something like a cloth or some cardboard between them so that they can be kept apart and close contact is avoided.

Beware of Some Materials

Some materials such as metal can be hazardous when it comes to using with glass.

If you are using metal components in your glass product, or using metal to attach it to something, then you must be careful.

When metal comes into contact with glass, it can often lead to scratching and this can cause problems with visibility.

If you’re adding any hazardous materials or extreme pressure then this should also be checked to make sure it is compatible and that the glass item you are using is strong enough to contain it and do it’s job properly.

Handle with Clean Hands

The final hint and tip is to always make sure your hands or gloves are clean when touching your glass, especially if it is being used for its visibility.

Glass is easy to stain, and if you are dealing with substances that are dark, then this can quickly lead to your glass becoming cloudy.

Also, if you are wearing gloves, these may contain some small bits of material that could cause damage to the glass such as scratching.

Try and always use a clean pair of gloves, and if handling with your bare hands, always give them a good clean first.

Cathode Ray Tubes

Custom Glass Manufacturing from Moore’s Glassworks

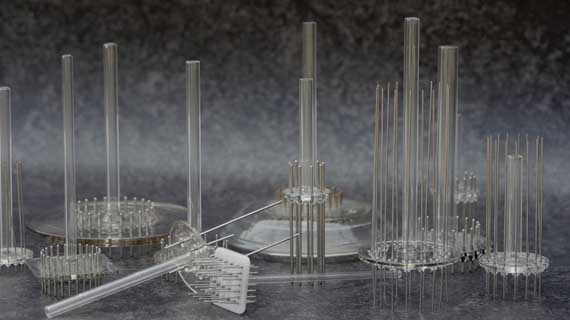

If you do require custom glass products that are always of the highest quality and to the exact dimension required, then why not get in touch with Moore’s Glassworks.

Our expert team of glassblowers have access to innovative auto-lathes and have years of experience in creating glass items that are perfect for the job at hand.

Want to know more? Then take a look at our range of products today.

Leave a Reply