The Role of Automation in the Glass Manufacturing Industry

https://moores-glass.co.uk/wp-content/uploads/2018/06/cathode-ray.jpg 1000 750 Matthew Morris Matthew Morris https://secure.gravatar.com/avatar/09048644f0c2340325fc98c2460d4a4f?s=96&d=mm&r=gHere at Moore’s Glassworks, we always look to be at the forefront of glass manufacturing.

While glass manufacturing has a history dating back centuries, the way it is done now looks very different.

One of the reasons glass is so commonplace in society and is so quick to manufacture, is automation. This can done on huge scales, and in many different ways.

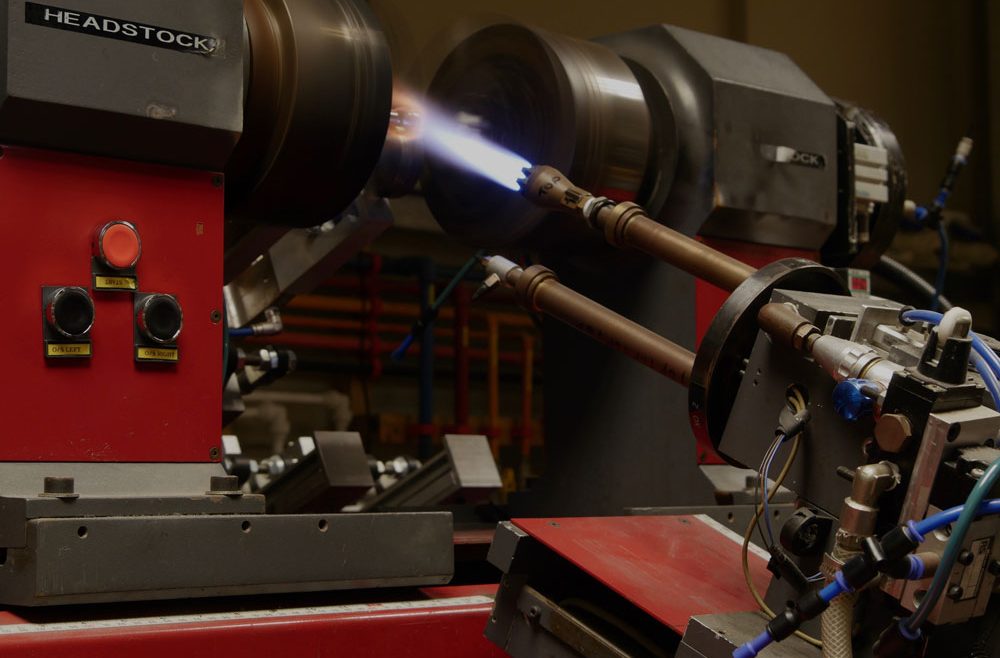

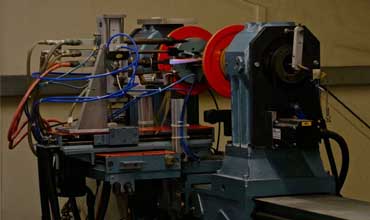

In our glass manufacturing plant, we use auto-lathes. These are state-of-the-art equipment that can create pinpoint glass products at amazing speeds.

But how did automation start in glass manufacturing? And why is it such a popular way of creating glass equipment?

Let’s take a look.

What do We Mean by Automation?

Automation refers to the use of technology to perform tasks or processes without human intervention.

This can include the use of machinery, robotics, artificial intelligence (AI), and computer software to complete tasks or operations that were previously performed by humans.

Automation is seen in most places you look, and continues to take more roles in modern society as technology advances. Think of the next time you stop at a traffic light, the fact it is a machine stopping traffic and not a human is a sign of automation becoming commonplace in society.

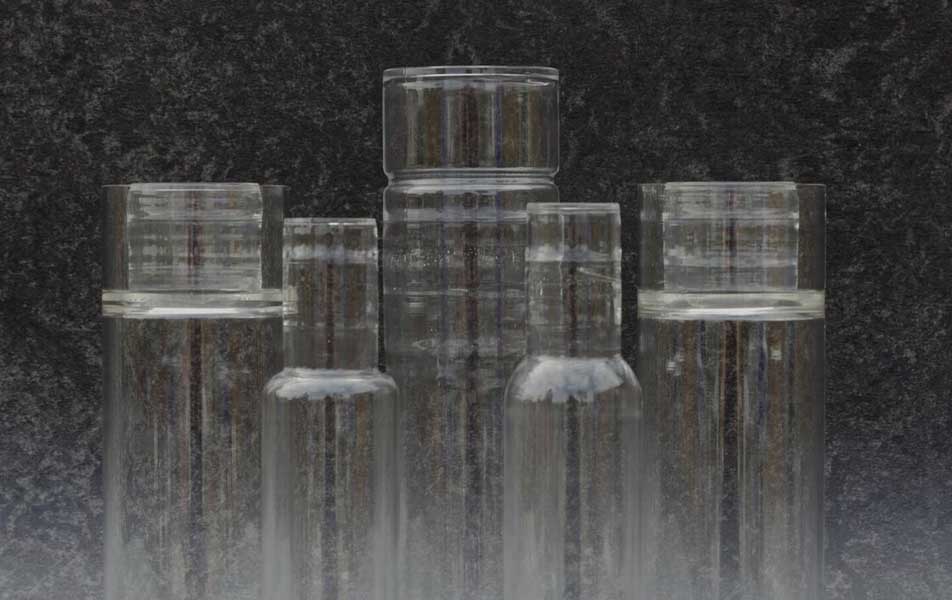

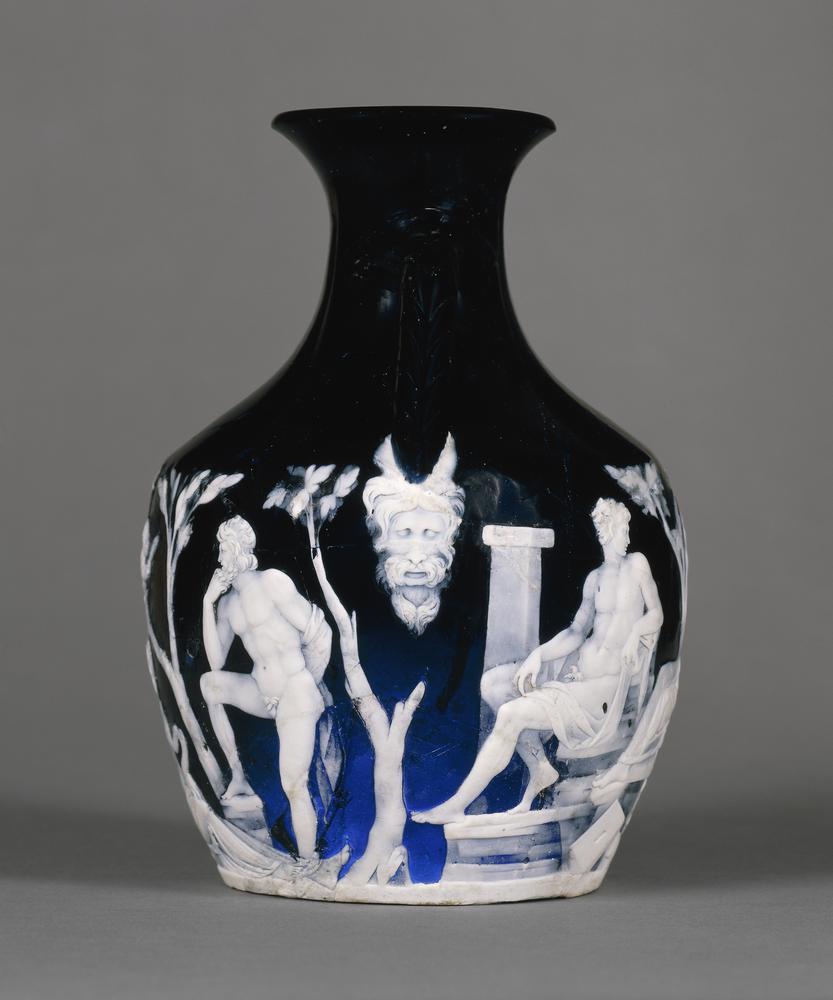

In the glass manufacturing industry, especially when dealing with products such as cathode ray tubes, vacuum viewports, and glass condom moulds, measurements have to be precise to ensure the product works as it should.

While a human hand can do this, it can be a time-consuming process, and that is why machines such as our auto-lathes are game-changers.

Automation has advanced many aspects of the glass manufacturing process, from design to creation and even packaging.

The History of Automation in the Glass Manufacturing Industry

Automation has played a significant role in the glass manufacturing industry, with a history spanning several decades.

But, as with most things, it wasn’t always this way.

So what happened to introduce automation in this field.

Let’s find out with a quick history.

Early Automation

In the early days of glass manufacturing, most of the work was done by hand.

However, in the mid-20th century, glass manufacturers began to adopt automation to increase production capacity and reduce labor costs.

This initial automation involved the use of simple machines such as conveyor belts, cranes, and mechanical presses.

While these may seem like simple machines, especially compared to some of the new advances in technology we see now, they completely revolutionized the way glass was manufactured, making it able to produce glass on huge scales.

Computerization

In the 1970s, glass manufacturers began to incorporate computer technology into their production processes.

This allowed for greater control over the manufacturing process and improved quality control.

Computerized control systems were used to regulate temperatures, monitor production, and manage inventory. We use computer technology on our auto-lathes to allow the user to carefully map out a product. All they have to do is input the figures, and the machine will do the rest, creating a glass product that fits the exact dimensions.

Robotics

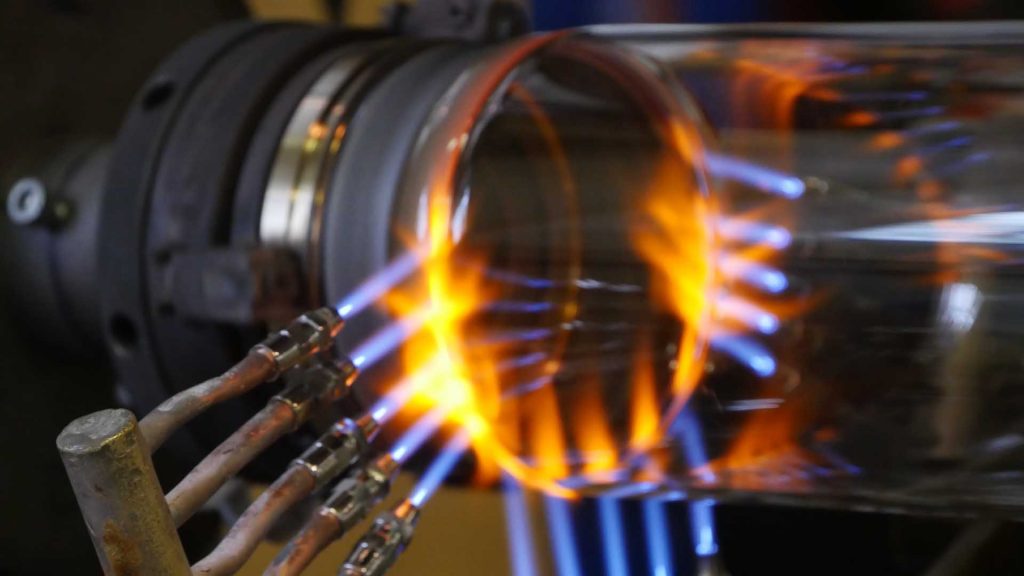

In the 1980s, glass manufacturers began to incorporate robotics into their production processes.

Robots were used to handle and move glass components, reducing the need for manual labor and increasing efficiency.

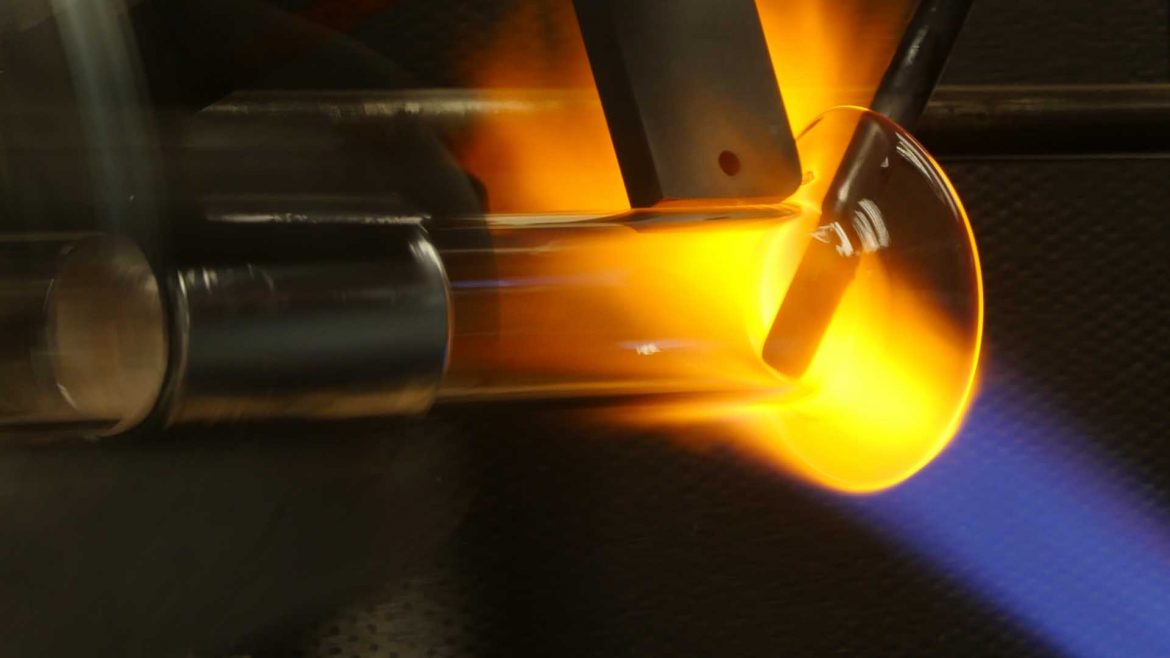

Robots were also used to perform tasks that were too dangerous or difficult for humans, such as working in high-temperature environments.

Glass manufacturing involves dealing with high temperatures, and using robots and machines, you can get much closer access to the project at hand, without burning yourself.

Advanced Automation

In the 1990s and 2000s, glass manufacturers continued to incorporate more advanced automation technologies.

This included the use of artificial intelligence (AI) and machine learning to improve the efficiency and accuracy of production processes.

Advanced automation also allowed for greater customization and flexibility in manufacturing, as well as improved safety and environmental sustainability.

Today, glass manufacturers continue to explore new ways to incorporate automation into their production processes.

And it’s easy to see why, as using automation to help manufacture glass comes with many benefits.

The Benefits of Using Automation for Glass Manufacturers

The use of automation has brought many benefits to the glass manufacturing industry, including:

- Increased productivity: One of the primary benefits of automation in glass manufacturing is increased productivity. Automated processes can perform tasks more quickly and efficiently than humans, and they can operate around the clock without the need for breaks or rest. This allows manufacturers to increase their production output and meet the demand for glass products more efficiently.

- Improved quality control: Automation can improve the quality control of glass products by eliminating errors caused by human error. Machines such as auto-lathes can measure and control temperature, pressure, and other factors that impact product quality with greater precision than humans. This results in more consistent and higher quality glass products.

- Reduced labor costs: By automating tasks that were previously performed by humans, glass manufacturers can reduce their labor costs. Automated systems can perform tasks more quickly and efficiently, and they do not require breaks, vacation time, or other benefits that are provided to human employees.

- Enhanced safety: Glass manufacturing can be a hazardous industry, with the risk of burns, cuts, and other injuries. By automating tasks that are dangerous for humans, manufacturers can improve the safety of their operations. Automated systems can also monitor and control hazardous conditions such as high temperatures, reducing the risk of accidents.

- Improved sustainability: Automation can help glass manufacturers to reduce their environmental impact by optimizing energy use, reducing waste, and improving the efficiency of production processes. This can result in significant cost savings, as well as a reduced carbon footprint.

- Flexibility and customization: Automation can provide glass manufacturers with greater flexibility and customization in their production processes, and can be reprogrammed quickly to accommodate changes in production requirements or to produce different types of glass products.

The benefits of automation are huge and clear to see, and as technology continues to evolve, we can expect to see even more benefits in the future.

Moore’s Glassworks: Custom Glass Manufacturers

Are you looking for custom glass manufacturing? Then look no further than Moore’s Glassworks.

We use automated equipment, as well as skilled glass blowers, to create glass products that are shipped all over the world.

Want to know more? Then get in touch today.