The Glass Manufacturing Process: What Happens at Moore’s Glassworks?

https://moores-glass.co.uk/wp-content/uploads/2018/07/New-slide-2-1024x576.jpg 1024 576 Matthew Morris Matthew Morris https://secure.gravatar.com/avatar/09048644f0c2340325fc98c2460d4a4f?s=96&d=mm&r=gThe glass industry manufacturing process contains many different elements depending on the job and the tools at hand.

At the heart of it though, is the process of glass forming. The differences come in factors such as if you’re using machinery or engineers, and the size of the job.

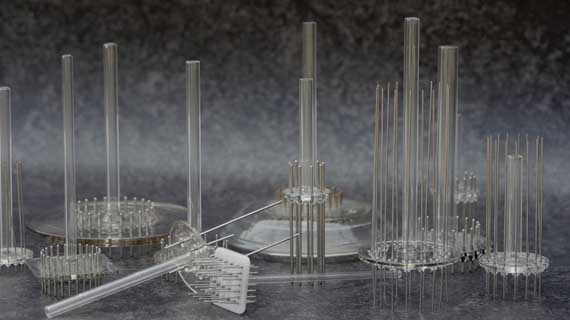

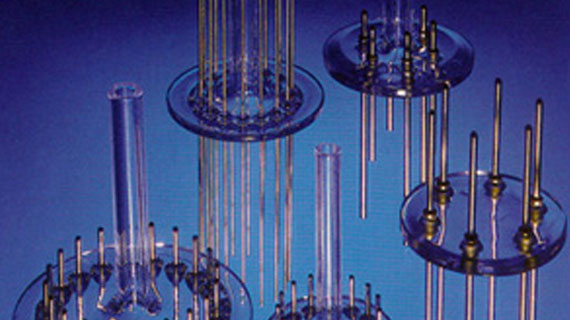

If someone is looking to produce multi-pin bases, the work carried out within the glassworks would be different to when creating a glass condom mould, but the science behind it all would be the same.

At Moore’s Glassworks, we use state-of-the-art machinery alongside expert professionals to manufacture glass that is sent all over the world and is used in many industries including science and the military.

But how does the relationship between man and machine work?

Let’s take a look.

Receiving the Order

The first thing that needs to happen for us to make a product is for a customer to get in touch.

Many businesses require our products to operate, and therefore it is vital we stick to their product descriptions accurately.

No matter the size of the job, our team of trained engineers and our auto lathe machinery can form our glass products to be just the way you need them.

All you need to do is let us know what you need, and we will produce it.

The Glass Manufacturing Process

Once we know the full details of the product we must manufacture, the process can begin.

Most of the products at Moore’s Glassworks are created by our skilled glassblowers and engineers.

While we do use the auto lathes for some jobs, all of our products are checked over by one of our engineers before it is shipped, to ensure it is of the highest quality.

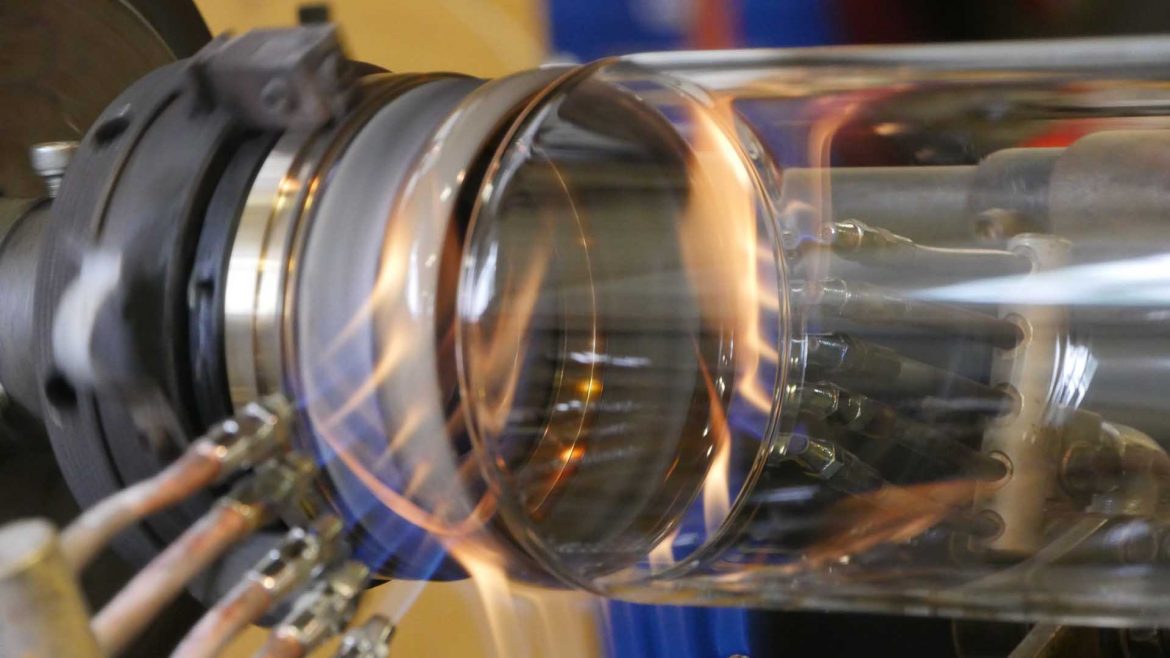

So, just what goes on when creating products such as cathode ray tube glass and vacuum viewports?

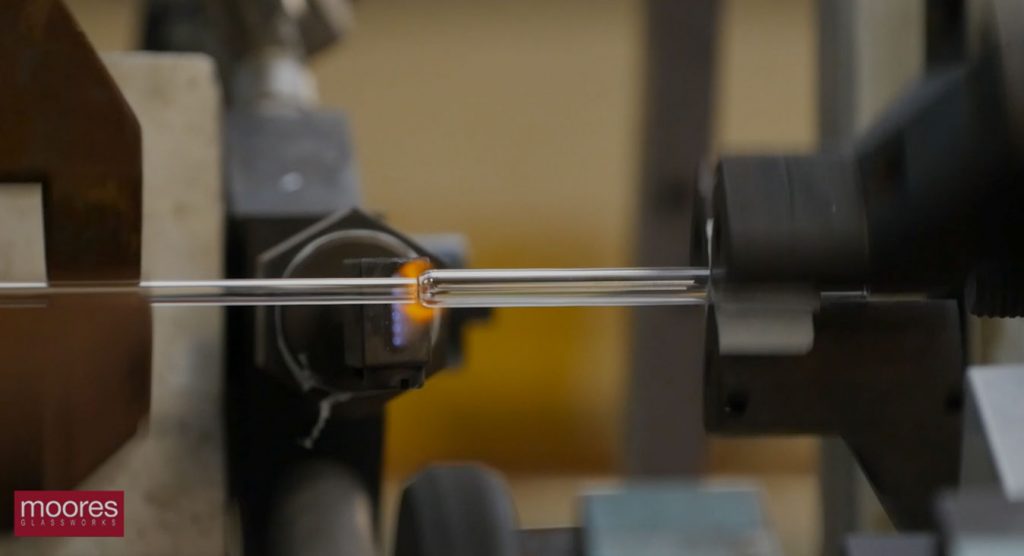

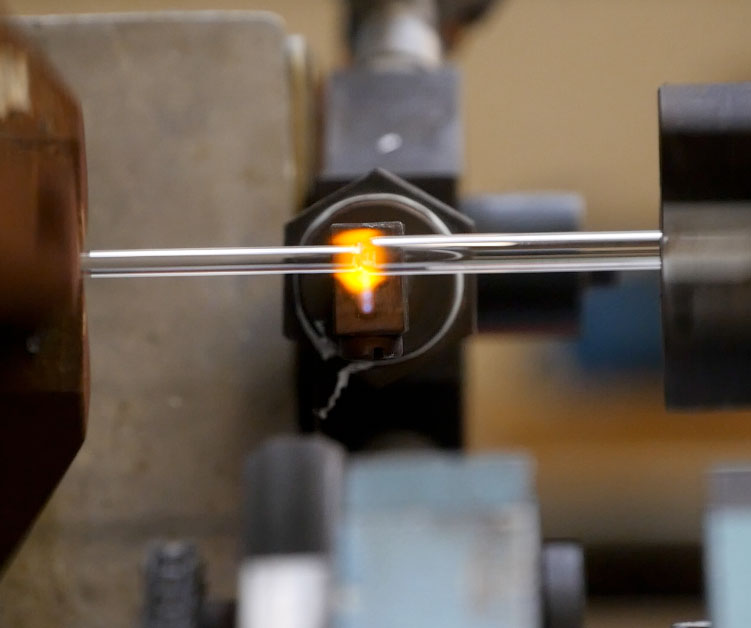

Well, if one of our glassblowers is working alone on a manual lathe, they will use hot forming techniques to mould the glass into the desired shape.

After making every adjustment to the glass, the work can be checked before the engineer works out their next move in the process.

Throughout the manufacture, extreme heat is applied to areas of the glass, allowing it to be shaped.

Through years of experience, our engineers are highly adept at judging the environment in which the process is taking place and working out the best steps to progress with the job.

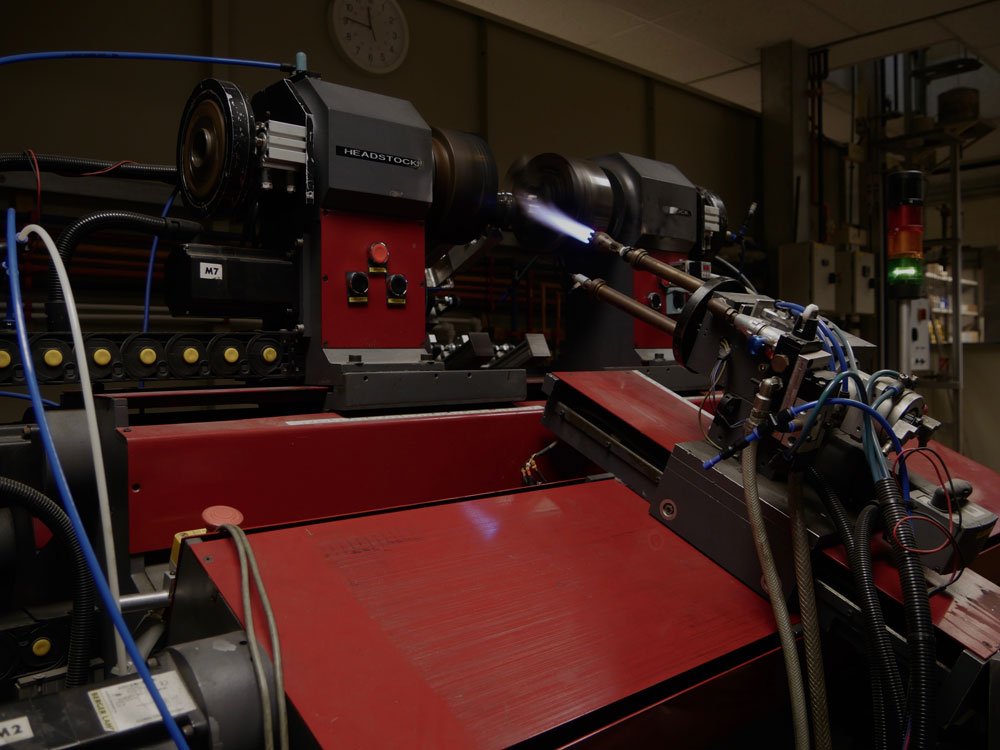

While our engineers always achieve stunning results, we use our very own auto lathe machines, which can do a very similar job, producing quick results and high consistency.

The way the auto lathes work is that the glass is placed in the machine, from where it is thermographically analysed throughout the process of pulling, pushing, blowing and many other methods of shaping the glass.

These auto lathes replicate the work of human engineers, but instead of an engineer visibly checking the work that is taking place, the auto lathe is constantly analysing the product through its thermographic readings.

Auto lathes have many benefits, including the fact that they can be programmed to produce large batches of identical products in quick succession.

If I’m making this sound easy, then I can assure you now that it is not.

Many different factors, such as the size of the job or the heat of the flame can have a big effect on the glass manufacturing process, and there are also plenty of hazards.

One of our auto-lathe machines

Hazards in Glass Manufacturing Industry

Despite a 50% decrease in accidents in the last ten years, there are still many potentially hazardous situations in the glass manufacturing industry. Here are three:

Injury

Like any manufacturing warehouse, there is the possibility of injury. With heavy-duty machinery in constant use, it is vital that full training is undergone prior to working in our building. We provide all staff with comprehensive training on the use of our machinery to ensure that everyone is aware of the best practices when it comes to operation. Also, we make sure all employees are trained in handling the glass products we manufacture to make certain that injuries are avoided.

Noise

Glass manufacturers, like any manufacturer, can be noisy. With machinery constantly in operation, this can really ramp up the volume. At Moore’s Glassworks, we try and keep noise to a minimum, and many of our machines can be used without the need for ear protectors. Of course, if one of our engineers did desire protection, we have heavy-duty ear protectors readily available.

Heat

When working with fire, there will always be a hazard. If not handled correctly, this can lead to injury, and therefore we take this very seriously in our warehouse. All of our staff undertake thorough training and are all experts in using fire in a safe and professional manner. Full protective equipment is also supplied if needed.

Quality Control

Of course, sometimes things don’t go to plan, and that’s why we have a strict quality control policy at Moore’s Glassworks.

Especially when not using our auto lathes, which are extremely precise, it is vital to check every product is safe and in the perfect condition to be shipped to our customers.

We are proud to say that our products are always of the highest quality and standard, and our quality checks are a huge part of this.

Nothing leaves our manufacturing plant without a full check, and that’s just one reason our customers love working with us.

Quality control at Moore’s Glassworks

Final Thoughts

Once the product is ready and fully checked, it can be stored in one of our warehouses (based in the UK and Belgium) before being shipped to our customer.

If you would need the service of our team at Moore’s Glassworks, then why not get in touch today and allow us to provide a quote.

From graded seals to photo ionisation detector glass bodies, we work to your needs and always produce a product of the highest quality.